1. Scope of this document

This document enables a company to achieve its feed safety objectives. It specifies requirements for a Feed Safety Management System (FSMS) which enables a company to provide safe feed products and feed services.

All requirements in this standard are generic and are intended to be applicable to all companies with activities in the feed chain, regardless of size and complexity. This ranges from companies which produce feed additives, feed materials, premixtures, compound feed or pet food, to companies which are involved in the trade, storage and transshipment and transport by road or rail of these products.

When creating this standard use has been made of the ISO22000:2018 Food safety management systems — Requirements for any organization in the food chain , which specifies requirements and conditions for a food safety management system. To a certain extent, the same requirements and conditions also apply to a management system which feed companies can implement to ensure the safety of feed. The use of ISO22000 is expressed in the same structure, and for a number of requirements and conditions in the same becoming and formulation of requirements and conditions. In this way, combining both standards is relatively easy. The complete text of the standard can be consulted in the NEN-EN-ISO 22000 standard, which can be obtained from NEN –www.nen.nl(https://www.nen.nl/en/nen-en-iso-22000-2018-en-248130).

This document allows any company, including smaller businesses, to set up a robust and reliable Feed Safety Management System. In addition, internal and/or external resources can be used to meet the requirements of this standard.

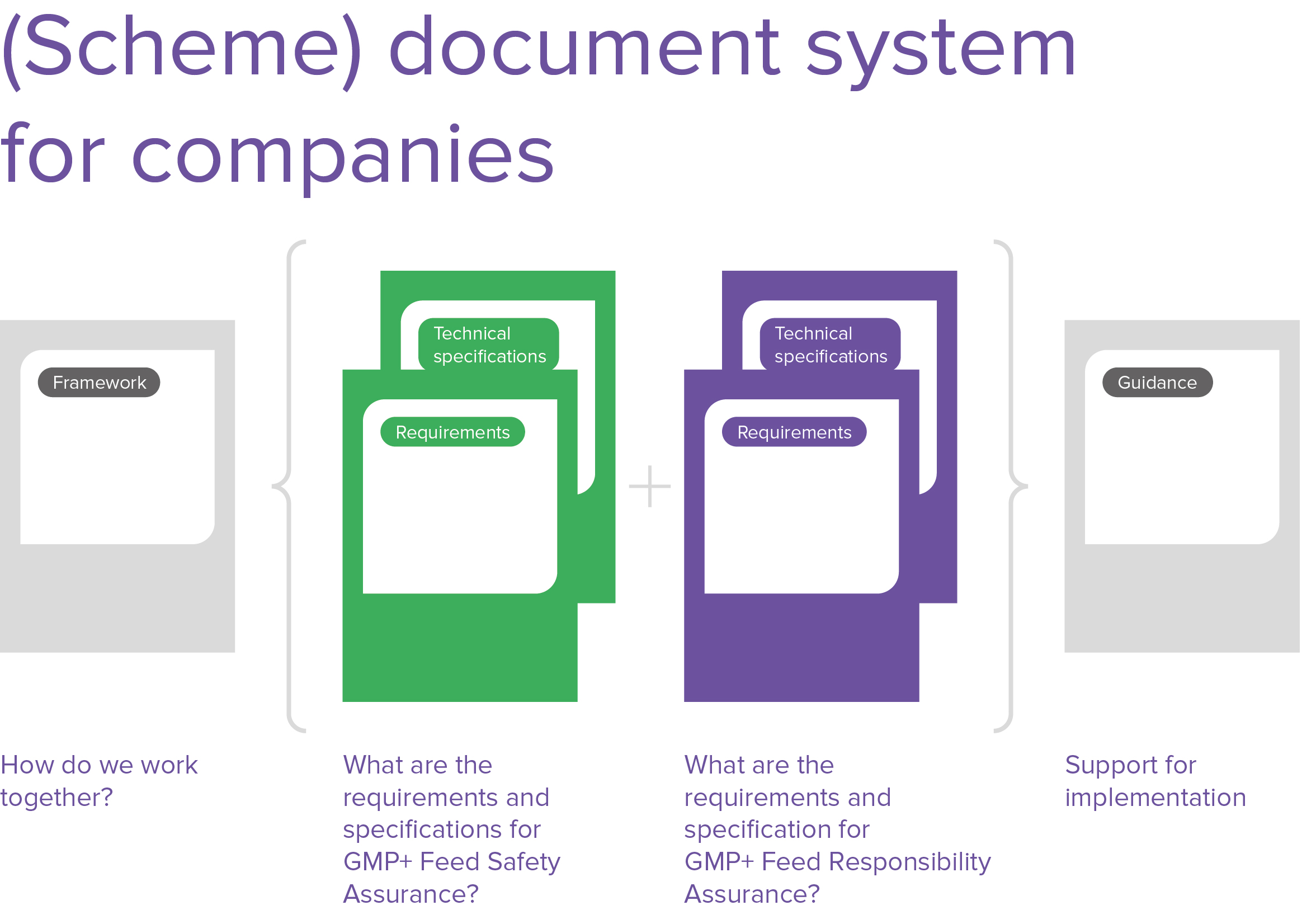

This document (together with the Technical Specifications) is part of the GMP+ FSA module. If a company demonstrates compliance with the requirements in this standard, a GMP+ FSA certificate can be granted by the Certification Body.

2. Normative references

Some of the requirements contained in this document (the Feed Safety Management Systems Requirements) refer to the GMP+ Technical Specifications (TS). These Technical Specifications explain in more detail a specific element of the Feed Safety Management Systems Requirement and must be considered as a normative part of the GMP+ FSA module.

Furthermore, some Technical Specifications are additional to this document (the Feed Safety Management Systems Requirements). These Technical Specifications must also be considered as a normative part of the GMP+ FSA module.

3. Terms and Definitions

See F0.2 Definition list.

4. The context of the GMP+ certified company

Every GMP+ certified company is part of the global feed and food chain. The company must therefore be very aware of this position. This relates not only to the locations where the feed activities take place, but also to where the company's GMP+ FSA assured products are marketed.

4.1. Compliance with Feed legislation and this Standard

The GMP+ certified company must comply with the applicable feed legislation. This relates to feed legislation:

- in the country in which the certified company is located;

- in the country where the feed is marketed.

- The GMP+ certified company must also comply with the relevant sections of the standard.

If the standard does not describe control measures for a specific situation, it is the responsibility of the GMP+ certified company to establish and implement additional control measures based on a HACCP study, as described in Chapter 8.

In all of the above cases, it is the most strict requirement which is applicable for GMP+ certified companies.

4.2. Understanding the Needs and Expectations of interested parties

The GMP+ certified company must safeguard that the delivered products and services comply with the applicable requirements of the GMP+ FC scheme and the needs from the relevant interested parties.

Helpful tip

There are a wide range of interested parties whose needs you need to think about regarding the GMP+ Feed Safety Management System. It can help to list them carefully. These interested parties can range from suppliers, customers, contracted transporters and providers of services like pest control, as well as silo cleaning, tank cleaning, harbor companies, certification schemes and port authorities.

4.3. Determining the scope of the Feed Safety Management System

The GMP+ certified company must determine the scope of the FSMS, by specifying:

- all activities, processes, products or services related to feed for which it is responsible. These include activities, processes, products and services carried out by/for third parties;

- all locations -- whether these are the property of the company or not -- including relevant administrative locations;

- which of the activities, processes, products or services on those locations are subject to GMP+ certification;

- it is possible to exclude activities, processes, products or services related to the production, trade, storage and transport of feed from the scope of GMP+ certification;

- other (feed and non-feed related) activities, processes, products or services as defined under c) that can have an impact on feed safety. The GMP+ certified company must ensure that these activities, processes, products or services do not have a negative impact on feed safety. See for more details TS1.10 Operational Activities § 1.10 Separation;

- The GMP+ certified company must always consider the requirements referred to in § 4.1 and § 4.2 when determining this scope.

All activities potentially influencing feed safety must be available for auditing. The scope must be documented and updated.

Helpful tip

This is complex matter. A great place to start reading about the scope of activities concerning GMP+ certification are the documents: F0.3 Scopes for certification and S9.3 Explanation of GMP+ feed chain.

Above we mention "activities and/or products which are not related to feed" here you can think about, for example, storage of fuels, agricultural vehicles, wood. These are not directly involved in the feed process but could potentially have a negative impact on feed safety.

4.4. Feed Safety Management System

The GMP+ certified company must establish, implement, maintain, update and continually improve a the Feed Safety Management System, in accordance with the requirements of the GMP+ standards. Attention must be paid to (the interaction between) the individual processes. Your Feed Safety Management System must control your processes, including the interaction between these processes.

When you use externally developed elements to establish your Feed Safety Management System, you must ensure, based on an assessment, that these elements are (made) suitable for your specific Feed Safety Management System.

Helpful tip

Externally developed elements can be (part of) a quality manual developed by a consultant or a HACCP study or Code of Practice carried out by an association, for example. Also think of the generic risk assessments, provided by GMP+ International as part of the Risk Management Tools.

5. Leadership

5.1. Commitment of the top management

The top management of a GMP+ certified company must safeguard that:

- the feed safety policy and the objectives of the FSMS are recorded;

- the FSMS requirements are integrated with the company's processes;

- resources are available to comply with the FSMS and to ensure its continuous improvement;

- the compliance with the FSMS and customer requirements are evaluated, maintained and communicated;

- persons are instructed and supported to take their responsibility to an effective FSMS.

5.2. Feed safety policy

5.2.1. Feed safety policy content

The feed safety policy implemented and maintained by the top management must:

- ensure the compliance with the relevant GMP+ documents, applicable (feed) legislation and customer requirements;

- fit the context and objectives of the organization;

- include a structure to define and evaluate the objectives of the FSMS, as described in Chapter 6;

- include the internal and external communications applicable to the FSMS;

- include the commitment to the continuous improvement of the FSMS and the necessary feed safety knowledge.

5.2.2. Communicating feed safety policy

Feed safety policy must be:

- kept as documented information;

- communicated and applied within the GMP+ certified company;

- available to interested parties.

5.3. Responsibilities

5.3.1. Responsibilities Top management

Top management must secure the responsibilities and authorities for the relevant roles are defined, communicated and understood within the company. Top management is ultimately responsible for the Feed Safety Management System.

Top management must establish responsibilities and authority for:

- safeguarding that the FSMS complies with the GMP+ requirements;

- establishing the Feed Safety Team(s) and the Feed Safety Team leader(s). If there is more than one Feed Safety Team, a coordinator must be assigned;

- establishing the Validation Team(s) and the Validation Team leader(s). The members of the Feed Safety Team can also be members of the Validation Team, but the Validation Team must include at least one independent member in order to avoid undue influence. If this is not possible, Top management may deviate from this as long as valid reasons are given. If there is more than one Validation Team, a coordinator must be assigned;

- nominating persons to start and document action(s).

5.3.2. Responsibilities of the Feed Safety Team Leader

The Feed Safety Team Leader is responsible for:

- the FSMS (incl. Hazard control plan as described in § 8.5) is implemented and updated;

- the activities of the Feed Safety Team are coordinated;

- the necessary training and competencies for the Feed Safety Team (§ 7.2) are secured;

- the Top management is informed on the performance of the FSMS and any need for improvement;

- the progress, set-up and maintenance of the FSMS are coordinated, in the event of more than one Feed Safety Team.

Helpful tip

Some staff members can fulfil multiple roles within a Feed Safety Team. You are also permitted to use resources from outside the company. But Top management always remains ultimately responsible for the FSMS.

5.3.3. Responsibilities of the Validation Team

The Validation Team must clearly document the persons involved on the team and the activities which they carry out.

5.3.4. Responsibilities of all persons involved

Everybody within the GMP+ certified company must notify potential and current issue(s) regarding the FSMS to the management.

6. Planning

6.1. FSMS Objectives

The GMP+ certified company must establish objectives for the FSMS at relevant roles and levels.The objectives of the FSMS must be:

- in line with the feed safety policy and the applicable legal requirements as mentioned in Chapter 4;

- quantifiable;

- monitored and verified;

- communicated;

- maintained and revised as appropriate;

- kept as documented information.

Helpful tip

When you first start to plan how to achieve the objectives for the FSMS, it's a good idea to set out the following as part of your project plan:

- the activities to be done;

- the resources needed;

- the responsible persons;

- the time frame to achieve;

- the assessment of the results.

6.2. Changes on the FSMS

The GMP+ certified company must take into consideration when changes are required on the FSMS:

- the objective of the changes and their potential impacts on feed safety;

- the continued integrity of the FSMS;

- the resources needed;

- the assigned roles and authorities.

7. Support

7.1. Resources

7.1.1. General

The GMP+ certified company must determine and provide the resources needed for setting up, implementing, maintaining, updating and continually improving the FSMS. The company must take into account the:

- capability and limitations of the internal resources;

- necessity of external resources.

Helpful tip

By "resources" here it is meant the people, infrastructure, work environment and other things which are required in order to set up a workable Feed Safety Management System.

7.1.2. People

The GMP+ certified company must ensure that the personnel responsible for operating and maintaining an effective FSMS are competent. This competence must be kept as documented information.

When external personnel is hired to perform activities related to the FSMS, the GMP+ certified company must keep documented information about the agreements or contracts that define their competency, responsibility and authority.

7.1.3. Infrastructure

The GMP+ certified company must provide the resources to determine and maintain the infrastructure necessary to comply with the requirements of the FSMS. Infrastructure can include:

- facilities (such as production and storage areas, loading compartments);

- equipment (including hardware and software);

- information and communication technology.

Helpful tip

See for more details TS 1.1 Prerequisite Program, Chapter 1 Infrastructure

7.1.4. Work environment

The GMP+ certified company must provide resources for a work environment necessary to comply with the requirements of the FSMS.

Helpful tip

Suitable work environment is affected by human and physical elements, for example, hygiene, temperature, humidity, natural light, air conditions and noise.

Note: See for more details TS1.1 Prerequisite Program, Chapter 2 Maintenance.

7.1.5. Management of suppliers

The GMP+ certified company must:

- establish and apply criteria for evaluating, selecting, monitoring of performance, and re-evaluation of external providers of processes, products and/or services which can have an impact on feed safety. These criteria must be based on a hazard analysis (see Chapter 8). At least the following requirements must be met. The GMP+ certified company must purchase processes, products and/or services from the suppliers, which:

- GMP+ FSA certified or;

- certified for another accepted standard or;

- assured by the GMP+ certified company via gatekeeper conditions. See TS1.2 Purchase for specific requirements.

- ensure adequate communication of requirements to external supplier(s);

- ensure that externally provided processes, products or services do not adversely affect the GMP+ certified company's ability to consistently meet the requirements of the FSMS.

Feed materials that are produced or purchased must be included in TS1.3 Product List. This does not apply to feed materials which are only processed in feed for non-food producing animals. Products that are not allowed to be used in feed are listed in TS1.4 Forbidden Products and Fuels.

The GMP+ certified company must keep documented information of the supplier assessment and any necessary actions related to it.

Helpful tip

When we say "external providers", we mean all processes, products and services, which you buy from suppliers which are needed to help you produce and/or deliver GMP+ assured feed. This also includes providers of raw materials, veterinary medical products, cleaning agents, and outsourced services such as pest control and maintenance.

The support documents S9.3 Explanation of GMP+ feed chain and S9.7 How to execute supplier assessments are very useful and provide more information.

7.2. Competence

To ensure the feed safety and the effectiveness of the FSMS, the GMP+ certified company must:

- clearly describe how it organizes the relevant personnel;

- determine the needed competence of the personnel - own and external;

- ensure that all personnel are competent by education, training, and/or experience;

- ensure that the Feed Safety Team has expertise and experience in implementing the FSMS. This includes (but is not limited to) the company's products, processes, equipment and feed safety hazards within the scope of the FSMS;

- where applicable, obtain the necessary competence, and assess the effectiveness of the actions taken;

- keep the evidence of competence as documented information.

Helpful tip

When we talk about "actions to acquire the necessary competence" think about your personnel who may have had relevant education, training, and coaching. If you do not have that knowledge in-house, consider hiring or contracting competent persons.

7.3. Awareness

The GMP+ certified company must ensure that personnel – own and external - related to the FSMS must be aware of:

- the feed safety policy;

- the objectives of the FSMS relevant to their activities;

- their influence on the effectiveness of the FSMS;

- the impact of not complying with the FSMS requirements.

7.4. Communications

7.4.1. General

When determining the internal and external communications relevant to the FSMS, the GMP+ certified company must specify the information to be communicated, the timeframe of communication, the responsible persons, the communication methodology and the target group(s) of the communication.

The GMP+ certified company must ensure that personnel - own and external - related to the FSMS understands the need of effective communication.

7.4.2. External communications

The GMP+ certified company must keep effective communications about feed safety with:

- suppliers of products and services and customers about:

- product information to enable the proper handling, storage, distribution and use of the product within the feed chain;

- the status of GMP+FSA feed and services. (SeeTS1.8 Labeling for specific requirements);

- identified feed safety hazards on the products/services that have to be controlled by other companies in the feed chain;

- contractual arrangements, inquiries and orders including their amendments;

- feedback -- including complaints;

- not meeting / exceeding of standards or other irregularities/nonconformities (see 8.7.2 Handling of potentially unsafe products).

- relevant competent authorities;

- other organizations that are relevant to the FSMS.

The GMP+ certified company must keep any external communication relevant to the FSMS as documented information.

Helpful tip

It is perhaps helpful to be aware that the Certification Body of the GMP+ certified company is also seen as a contractor.

7.4.3. Internal communications

The GMP+ certified company must implement an effective communication system to inform on time about feed safety issues within the organization, particularly to the Feed Safety Team.

The Feed Safety Team must include the relevant information when updating the FSMS (§4.4 and §10.3).

Top management must include the relevant information as input to the management review (§9.3).

7.5. Documented information

7.5.1. General

The GMP+ certified company must include in the FSMS, the documented information concerning the:

- feed safety policy and feed safety objectives;

- requirements by the GMP+ scheme;

- measurement for the effectiveness of the FSMS;

- required information by national and international legislation and customers;

- scope of the FSMS (Chapter 4).

Helpful tip

Several factors can impact the quantity of documented information in the FSMS kept by GMP+ certified companies, for example:

- the size of company

- type and complexity of activities, processes, products and services;

- the competence of personnel.

7.5.2. Creating and Updating

The documented information of the GMP+ certified company must:

- be identified (eg a title, date, author, or reference number);

- have an appropriate format (eg language, software version, graphics) and media (eg paper, electronic);

- have suitable and adequate information.

7.5.3. Control of documented information

The GMP+ certified company must have the documented information required by the FSMS available, suitable for use and protected (eg from loss of confidentiality, improper use, or loss of integrity).

For the control of documented information, the GMP+ certified company must address the following, as applicable:

- distribution, access, retrieval and use;

- storage and preservation, including preservation of legibility;

- control of changes (eg version control);

- retention and disposition. Documented information must be kept at least three years unless a longer storage period is required according to the applicable feed legislation or other regulations.

The relevant documented information of external origin – determined by the GMP+ certified company to be used for the planning and operation of the FSMS – must be identified and controlled. Documented information retained as evidence of conformity must be protected from unintended alterations.

8. Operation

8.1. Operational Planning and Control

The GMP+ certified company must plan, implement, control, maintain and update the processes needed to meet requirements for the realization of safe feed products by:

- establishing criteria for the processes;

- implementing control of the processes in accordance with the criteria;

- keeping documented information to demonstrate that the processes have been carried out as planned.

The GMP+ certified company must control planned changes and review the consequences of unintentional changes, mitigating any negative effects.

The GMP+ certified company must ensure that outsourced processes are controlled (see §4.3).

8.2. Prerequisites (PRPs)

The GMP+ certified company must establish Prerequisite programs (PRPs) that are:

- suitable to the organization and its context concerning feed safety;

- suitable to the size and type of the operation and the nature of the products being produced, stored and/or transported;

- implemented within the organization according to the FSMS scope;

- approved by the Feed Safety Team.

- complying with applicable feed safety regulations and customer needs (see Chapter 4).

The GMP+ certified company must take into account the following items when establishing Prerequisite programs (PRPs):

- structure, layout of buildings including employee facilities;

- supplies of air, water, energy and other utilities;

- pest control, waste and sewage disposal and supporting services;

- equipment suitability and its cleaning and maintenance;

- cross contamination prevention;

- cleaning and disinfecting;

- personal hygiene;

- product information/consumer awareness;

- other factors, as appropriate.

The Prerequisite programs (PRPs) must at least be in accordance with TS1.1 Prerequisite program. The GMP+ certified company is responsible to select the applicable requirements.

The GMP+ certified company must have documented information regarding the implementation, monitoring and verification of the Prerequisite programs (PRPs).

8.3. Traceability system

All products that can have an impact on feed safety (GMP+ FSA assured or non-GMP+ FSA assured feed) must be traceable in all stages of production, processing and distribution. The traceability system must be able to identify incoming material from the suppliers to delivery of the end product. See for more details TS1.1 Prerequisite Program, Chapter 10 Traceability system.

The required information must be available for GMP+ International and competent authorities within 4 hours unless the authorities determine a shorter timeframe.

Documented information as evidence of the traceability system must be retained for a defined period, as stated in §7.5. The GMP+ certified company must verify the effectiveness of the traceability system.

If the GMP+ certified company is the owner of the goods, samples must be taken from incoming and/or outgoing feed in accordance with TS1.6 Sampling. A sample needs to be taken of the incoming and outgoing feed if it is sent out in a different form than it was received in. Samples must be kept available for the competent authority. The company can make written agreements with third parties on taking and storing of samples.

Helpful tip

The support document S9.8 How to develop traceability systems document, is very useful and provides more information about how to set up an internal traceability procedure.

Helpful tip

The 4-hour period noted above means that as soon as the GMP+ certified company receives the request to provide the required information -- it has a maximum of 4 (consecutive) hours to provide that information.

8.4. Incident management

8.4.1. General

Top management must ensure procedures to respond to potential incidents that can have an impact on feed safety or to the role of the GMP+ certified company in the feed chain.

The GMP+ certified company must keep documented information to manage these incidents.

8.4.2. Handling of Incidents

The GMP+ certified company must:

- respond to incidents by:

- identifying the applicable legal requirements;

- communicating within the company;

- communicating to interested parties (eg suppliers, customers, relevant authorities, media);

- mitigate the consequences of the incident (see § 8.7.2);

- review and, where necessary, update the documented information after the occurrence of any incident or tests.

Note: Examples of incidents related to feed safety are: natural catastrophes, workplace accidents, public health emergencies and disruption of essential services like water, electricity or refrigeration.

8.5. Hazard Control

8.5.1. Preparation for hazard analysis

8.5.1.1. Description of ingredients

The GMP+ certified company must keep documented information up-to-date about all feed materials, feed additives and processing aids as far as needed for identifying hazards and do a risk assessment (see § 8.5.2.2). The following information must be documented:

- microbiological, chemical and physical characteristics;

- composition of the feed ingredients, including additives and processing aids;

- origin (eg animal, mineral, vegetable, fermentation etc.);

- place of origin (provenance);

- production method;

- packaging;

- method of delivery;

- storage conditions and shelf life;

- preparation and/or handling before use or processing;

- feed safety limits for feed ingredients, feed additives and processing aids (TS1.5 Specific Feed Safety Limits);

- legal requirements (see § 4.1);

- product name or similar identification.

8.5.1.2. Description of end products

The GMP+ certified company must keep documented information up-to-date about the end-products to the extent needed to conduct a risk assessment (see § 8.5.2.2). The following must be documented:

- product name or similar identification;

- composition of the feed: ingredients and auxiliary substances used (incl. feed additives and processing aids);

- biological, chemical and physical characteristics;

- storage conditions and shelf life;

- packaging;

- labeling relating to feed safety and/or instructions for handling, preparation and intended use;

- method of distribution and delivery;

- legal requirements (see § 4.1);

- feed safety limits for feed (TS1.5 Specific Feed Safety Limits).

8.5.1.3. Intended use

The intended use must be considered and must be maintained as documented information to the extent needed to conduct a risk assessment (see § 8.5.2.2). The following must be documented:

- intended use

- preparation instructions;

- instruction for feeding (if applicable: including withdrawal periods);

- storage conditions;

- conditions regarding transport and conditions for the place of delivery;

- shelf life;

- legally required information on the packaging and/or in accompanying documents;

- reasonably expected incorrect handling or misuse of the product

Helpful tip

An example of such misuse is giving sheep feed products with a high copper content intended for goats and other livestock.

Sheep will be poisoned if they consume feed with a high copper content. This is one of the most common causes of sheep poisoning.8.5.1.4. Flow diagrams and Description of processes

The Feed Safety Team must establish, maintain and update flow diagrams and a floor plan as documented information for each feed (group), feed ingredient (group).

When conducting a hazard analysis, flow diagrams must be used as a tool for identifying and assessing feed safety hazards.

Helpful tip

You are permitted to create product groups. When you create product groups, you should combine products with the same characteristics, produced using similar processes. Be sure not to overlook the specific risks of individual products when creating groups.

8.5.1.4.1. Preparing flow diagrams

Flow diagrams must be detailed enough to conduct a hazard analysis. Flow diagrams must include:

- representation of all the individual steps in the process sequence (from purchasing to delivery), customer returns, rework recycling and waste which may be produced during the process;

- any outsourced processes;

- where raw materials, ingredients, processing aids, packaging materials, utilities and intermediate products enter the flow;

- where end-products, intermediate products and by-products are produced.

8.5.1.4.2. Preparing a floor plan

When relevant the whole infrastructure of the company location must be shown in a floor plan, including;

- the production units, storage areas and personnel facilities;

- machinery and equipment;

- the routing of feed and raw material through the organization in order to make any cross-contamination points visible.

8.5.1.4.3. Validation of the Flow diagrams and Floor Plan

The Feed Safety Team must validate on-site the accuracy of the flow diagrams and the floor plan, update where appropriate and keep as documented information. The Feed Safety Team can delegate this action to the Validation Team or another representative with knowledge of the process(es) and the HACCP system.

8.5.2. Hazard analysis

8.5.2.1. Hazard identification

The Feed Safety Team must identify and document all feed safety hazards which may have a negative effect on the safety of the product, type of process and process environment.The identification must be based on:

- The information and data collected in the previous HACCP steps (§ 8.5.1);

- experience;

- relevant internal and external information including epidemiological, scientific and other historical data;

- information from the feed chain on feed safety hazards related to the safety of the end-products, intermediate products and the feed and food at the time of consumption;

- legal requirements;

- the generic risk assessment from the Risk Managment Tools (RMT);

- the fact sheets of undesirable substances and products from the

- Risk Managment Tools (RMT).

Hazards must be analyzed in sufficient detail to enable risk assessment and the selection of appropriate control measures.The Feed Safety Team must identify which hazard can be present, be introduced, increased or remain at each process step. The GMP+ certified company must identify the hazards of:

- the links before and after in the feed chain;

- all steps in the flow diagram;

- the process equipment, infrastructure, process environment and persons.

For each hazard, the Feed Safety Team also establishes and records a feed safety limit whereby there is at least compliance with the statutory feed safety limits and those laid down in TS1.5 Specific Feed Safety Limits.

8.5.2.2. Risk Assessment

The Feed Safety Team must conduct a risk assessment for each identified feed safety hazard, to determine whether preventing or reducing the hazard to an acceptable level is critical for the processing of safe feed. The GMP+ certified company must determine for each feed safety hazard:

- the likelihood of occurrence in the end product prior to application of control measures;

- the severity of its adverse feed safety effects.

The risk assessment methodology used must be described, and the outcome of the risk assessment must be kept as documented information.

Helpful tip

The support document S9.4 Applying HACCP assessment document, provides a useful example methodology for risk assessment. GMP+ certified companies may use this or a different methodology to do the risk assessment.

8.5.2.3. Establishing Critical Control Points (CCPs)

The Feed Safety Team must determine appropriate control measure(s) that will prevent or reduce the feed safety hazards within defined feed safety limits.

For each control measure, the Feed Safety Team must establish whether this control measure is the final measure in the process of controlling this hazard. If so, then this is called a Critical Control Point (CCP). The reasons for setting up a Critical Control Point (CCP) must be documented.

The decision-making process and outcome of the determination of the control measures must be documented.

Helpful tip

Critical control points (CCPs) can also be set up with the help of a decision tree as explained in the S9.4 Applying HACCP assessment document.

8.5.3. CCP control

8.5.3.1. Determination of feed safety limits for CCPs

To determine whether a control measure works effectively, the Feed Safety Team must determine the following for each Critical Control Point (CCP):

- which parameters must be measured, analyzed or observed, and

- which feed safety limits apply for these parameters.

When determining feed safety limits, the GMP+ certified company must:

- ensure that applicable statutory and regulatory requirements are identified;

- ensure that applicable feed safety limits are identified as laid down in GMP+ FSA module (TS1.5 Specific Feed Safety Limits);

- consider the intended use of end products;

- consider any other relevant information.

The reasoning behind why the GMP+ certified company decided on specific Feed Safety Limits must be kept as documented information.

If there are no legal or GMP+ feed safety limits for a certain type of feed, GMP+ certified companies are responsible for setting the feed safety limits in their HACCP study.

Research must be based on literature studies, information from the sector, etc.

If there is both a legal feed safety limit and a GMP+ feed safety limit for a certain type of feed, the most strict feed safety limit applies.

8.5.3.2. Monitoring CCPs

A monitoring plan must be established for each control measure at each CCP to identify any failure to remain within the feed safety limits. The monitoring plan must include all analyzes relative to the feed safety limits.

The monitoring plan must consist of documented information, including:

- analyzes or observations that deliver results within an adequate time frame;

- the methods of sampling;

- the frequency of the sampling;

- responsibility and authority related to sampling;

- monitoring methods or equipment used;

- calibration methods or equivalent methods for verification of reliable analysis or observations;

- monitoring frequency;

- monitoring results;

- responsibility and authority related to monitoring;

- responsibility and authority related to evaluation of monitoring results.

The monitoring method and frequency at each CCP must be capable of detecting as fast as possible any failure to comply with the feed safety limits.

The GMP+ certified company must ensure proper identification and storage of samples taken for monitoring during an appropriate time as stated in TS1.6 Sampling. Retained samples must be kept available for the competent authority. The company can make written agreements with third parties on taking and storing of samples.

The monitoring plan must at least be in accordance with TS1.7 Monitoring. The company must justify the structure of the monitoring plan.

The monitoring methods must be suitable to achieve planned results. If measurement and monitoring takes place by the way of an analysis, this must be carried out by an approved laboratory. See TS1.2 Purchase .

8.6. Validation & Verification

8.6.1. Validation

The Validation Team (§5.3.3) must validate the HACCP plan prior to its implementation and after any changes are made. The purpose of validation is to ensure that the hazards which were established by the Feed Safety Team are complete and correct and that they are effectively controlled using the proposed control measures, the monitoring plan and the corrective actions.

The Feed Safety Team must modify and re-assess the control measure(s) and/or combination(s) of control measure(s) when they are not capable of preventing or reducing the feed safety risk.

The Validation Team must keep as documented information the validation methodology and the evidence that the control measure(s) are effective to prevent or reduce the feed safety risk(s).

Helpful tip

It's useful to remember that "modify" can also mean changes in control measures and/or changes in the production technologies for raw materials, end-product descriptions, methods of distribution and the intended use of the end-products.

8.6.2. Verification

8.6.2.1. Verification of the HACCP plan

The GMP+ certified company must implement and maintain verification activities. The verification preparation must define the objectives, methods, frequencies and responsibilities. The verification must be carried out by the Feed Safety Team and must demonstrate that:

- the HACCP plan is effective and up to date;

- hazard levels are within identified acceptable levels;

- other actions regarding the HACCP plan are implemented and effective.

8.6.2.2. Analyzing the results of verification activities

The GMP+ certified company must implement the corrective actions in accordance with §8.7.1 if samples of the end-products or direct process samples are not complying with the established feed safety limits (see TS1.5 Specific feed safety limits).

The Feed Safety Team must analyze the verification results at least once per year and use this as input for the Management review (see §9.3).

8.7. Control of non-conforming products and processes

8.7.1. Corrections and Corrective actions

If feed safety limits are not met (nonconformities occur), the Feed Safety Team must specify corrections and corrective actions to be taken and must ensure that action is taken to remove the observed nonconformity that ensures:

- the potentially unsafe products are not released;

- the cause of the nonconformity is identified;

- the parameter(s) controlled at the CCP is (are) returned within the feed safety limits;

- recurrence is prevented (verification of corrective action).

The Feed Safety Team must make corrections in accordance with §10.1. See also §8.7.2. regarding (potentially) unsafe products.

8.7.2. Handling of potentially unsafe products

8.7.2.1. General

The GMP+ certified company must take action(s) to prevent potentially unsafe products from entering the feed and/or food chain, unless the company can demonstrate that the specific feed safety hazard(s) is (are) reduced to defined feed safety limits §8.5.3.1.

8.7.2.2. Evaluation of potentially unsafe products

The GMP+ certified company must evaluate each nonconforming batch of products to determine if the products are safe or unsafe. Products must be considered as unsafe if:

- the feed safety limit(s) of undesirable substances in feed are exceeded, as mentioned in legislation or/and TS1.5 Specific feed safety limits,

- the GMP+ certified company has determined that the nonconformity or irregularity related to feed safety aspects are not controlled and can have consequences for other companies, even if there is no legislation and/or under TS1.5 Specific feed safety limits.

Products that are under the control of the GMP+ certified company and that have been determined as unsafe must be handled in accordance with §8.7.1.

The controls, evaluation for release of products, and related responses from relevant interested parties and authorization for dealing with potentially unsafe products must be kept as documented information.

If a product is determined unsafe, the GMP+ certified company must notify relevant interested parties. If products have left the control of the GMP+ certified company, the company must also notify relevant customers and initiate a withdrawal/recall (see §8.7.2.4).

If the GMP+ certified company is the owner of the goods, the company must then also notify GMP+ International and the Certification Body within 12 hours of detection or confirmation. GMP+ International must be notified via the EWS notification form which is available on the GMP+ International website.

The GMP+ certified company must establish and maintain documented information for notifying GMP+ International, the Certification Body and other relevant interested parties.

Note: Interested parties can, for example, be statutory and regulatory authorities, customers and/or suppliers. If the GMP+ certified company assesses the situation as being under control, the 12-hour notification deadline may be extended.

8.7.2.3. Non-compliant products disposal

The GMP+ certified company must handle the nonconforming products according to one of the following options:

- reprocessing or further processing to ensure that the products comply with the relevant feed safety limits; or

- destination to another use different than feed; or

- destroying and/or disposing as waste.

The GMP+ certified company must keep documented information on the destruction / disposition of non-conforming products, including the approval of the authorizing person(s).

8.7.2.4. Withdrawal / Recall

The GMP+ certified company must have a documented procedure to withdraw/recall unsafe products as quickly as possible (§8.7.2.2).

The GMP+ certified company must keep documented information about:

- the notification of relevant interested parties;

- the handling of withdrawn/recalled products;

- the actions taken.

Withdrawn/recalled products must be secured or held under the control of the GMP+ certified company until they are managed according to §8.7.2.3.

The GMP+ certified company must keep documented information regarding the cause, size and the result of a withdrawal/recall. This information must be used as input for the management review (see §9.3).

The GMP+ certified company must verify the withdrawals/recalls procedure at least once a year and keep documented information about it.

For more information see the support document S9.9 Executing a successful recall.

9. Assessment of the FSMS performance

9.1. Monitoring, Measurement, Analysis and Assessment

9.1.1. General

The GMP+ certified company must evaluate the performance and effectiveness of the Feed Safety Management System. This includes determination of:

- what needs to be monitored and measured;

- the methods for monitoring, measurement, analysis and evaluation, as applicable, to ensure valid results;

- when the monitoring and measuring must be performed;

- when the results from monitoring and measurement must be analyzed and evaluated;

- who must analyze and evaluate the results from monitoring and measurement.

The GMP+ certified company must keep appropriate documented information as evidence of the results.

9.1.2. Analysis and Assessment

The GMP+ certified company must analyze and assess monitoring and analyzes results, including at least the results of verification activities related to PRPs and the hazard control plan (§8.6.2), as well as internal audits (§9.2) and external audits. The assessment must:

- demonstrate that the performance of the FSMS is according to the requirements established by the GMP+ certified company;

- establish the necessity of updating or improving the FSMS;

- identify the tendency of potentially unsafe products or process failures;

- gather information for planning the internal audit program;

- demonstrate that corrections and corrective actions are effective.

The GMP+ certified company must keep as documented information the results of the analysis and any resulting activities and must use it as input for the management review § 9.3) and updating the FSMS (§10.3).

Note: Statistical techniques can be used as methods to analyze data.

9.2. Internal audit

The GMP+ certified company must conduct internal audits at planned intervals to demonstrate that the FSMS:

- complies with:

- own FSMS requirements;

- the GMP+ documents;

- has been effectively implemented and maintained.

The GMP+ certified company must:

- plan, establish, implement and maintain an internal audit procedure including:

- scope and audit criteria;

- an audit frequency of at least once per year;

- methods;

- responsibilities;

- planning requirements and reporting.

- during the development of the audit program(s) take into consideration:

- the importance of the processes concerned;

- changes in the FSMS;

- the monitoring results and previous audits;

- the selection of competent auditors to secure the objectivity and the impartiality of the audit process;

- that audits results are reported to the Feed Safety Team and relevant management;

- to keep documented information of the audit program and the audit results;

- that corrections and corrective actions are taken within a defined deadline;

- that the FSMS meets the intent of the feed safety policy (§ 5.2), and objectives of the FSMS (§6.1).

The GMP+ certified company must verify the actions taken and report the verification results.

9.3. Management review

9.3.1. General

The minimum frequency of the management review of the FSMS done by the top management is at least once per year to keep the FSMS suitable, adequate and effective.

9.3.2. Management review input

The management review must include:

- the progress of actions from previous management reviews;

- changes in the organization relevant to the FSMS;

- information on the performance and the effectiveness of the FSMS, regarding:

- the compliance with legislation and regulations (§4.1);

- the FSMS updates (§4.4 and §10.3);

- monitoring and analysis results;

- results of verification activities related to PRPs and the HACCP Plan (Chapter 8);

- nonconformities and corrective actions;

- results of internal and external audits;

- inspections (eg legal, customer);

- performance of external suppliers;

- achievement of the objectives of the FSMS.

- the suitability of resources (eg personnel, equipment);

- occurrence of any early warnings, incident (§8.4.2) or withdrawal/recall (§8.7.2.4);

- relevant information related to feed safety, including requests and complaints, from interested parties (eg customers and suppliers) (§7.4.2 and §7.4.3);

- opportunities for continuous improvement.

9.3.3. Management review output

The results of the management review must include:

- decisions and actions related to continuous improvement;

- any need for updates and changes to the FSMS.

The GMP+ certified company must keep documented information as evidence of the results of management reviews.

10. Improvement

10.1. Nonconformity and Corrective actions

The GMP+ certified company must immediately:

- respond to the nonconformity and, as applicable:

- control and correct it;

- handle the consequences;

- assess if the action(s) taken to eliminate the cause(s) of the nonconformity will avoid reoccurrence, by:

- reviewing the nonconformity;

- defining the root cause of the nonconformity;

- analyzing if similar nonconformity exists, or could occur;

- implement any action needed;

- review the effectiveness of any corrective action tasks;

- update the FSMS, if necessary.

Corrective actions must solve the root cause(s) of the nonconformity.

The GMP+ certified company must keep documented information regarding:

- the description of the nonconformity and any actions taken;

- the results of any corrective action.

10.2. Continuous improvement

The GMP+ certified company must continuously improve the FSMS. Top management must ensure that the organization improves the FSMS by:

- establishing feed safety policy and objectives (Chapter 4);

- communication (§7.4);

- management reviews (§9.3);

- audit results (internal and external) (§9.2);

- analysis of results of verification activities (§8.6.2);

- validation of control measure(s) and combination(s) of control measure(s) (§8.6.1);

- corrective actions (§8.7.1) and

- FSMS updating (§10.3).

10.3. Update of the FSMS

Top management must ensure that the FSMS is continuously updated. The Feed Safety Team must evaluate the FSMS at planned intervals. The Feed Safety Team must consider whether it is necessary to review the hazard analysis (§8.5.2), the established hazard control plan (§8.5.3) and the established Prerequisite Programs PRPS (§8.2).

The updating activities must be based on:

- internal and external communication, (§7.4);

- other information concerning the FSMS;

- output of the FSMS verification (§9.1.2);

- output from management review (§9.3).

The GMP+ certified company must keep as documented information the FSMS updating activities and must use it as input to the management review (§9.3).

Risk Management tools

That was a lot of information to digest and one might ask, what is the next step? Luckily we can offer support for the GMP+ Community when doing this. We provide support by means of various tools and guidances but as each company has a shared responsibility to feed safety, and therefor tailor-made solutions cannot be offered. However, we do help by explaining requirements and providing background information about the requirements. □

We have developed various supporting materials for the GMP+ Community. These include various tools, ranging from Frequently Asked Questions (FAQ) lists to webinars and events.

Supporting materials related to this document (Guidelines and FAQs)

We have made documents available which give guidance to the GMP+ requirements as laid down in the module GMP+ FSA and GMP+ FRA. These documents give examples, answers to frequently asked questions or background information.

Feed Fraud

Even when all feed safety requirements are applied things can go wrong. Did you even think of the possibility that fraud could have been committed? There is information available that helps you in getting insights on fraud which effects your company, focused on the prevention of feed fraud.

Early Warning System (EWS)

When you detect (possibly) unsafe feed, you have to report this to GMP+ International. Together we can prevent consequential damage to your company and the feed chain (as much as possible). Safe feed is, and remains, a joint responsibility. How this works is explained on our website.

Risk Management tools (RMT)

Risk Management Tools (RMT) provides valuable and up-to-date information about potentially high-risk feed. The products vary from flow charts of production processes including the risks (Risk Assessments) and studies on undesirable substances (fact sheets).

Where to find more about the Risk Management tools? Fact sheets More information: GMP+ Platform Product list More information: Product List Risk Assessments More information: GMP+ Platform GMP+ Monitoring database More information: GMP+ Monitoring database Support documents More information: Support documents |