1. Introduction

This standard is a stand-alone document which includes requirements for guaranteeing the safety of feed and food transport via inland waterway shipping and short sea shipping. This document has been approved by the Dutch Government as a Guide to Good Practice for Inland Waterway Transport. The Dutch ‘Inland Waterways Guide to Good Practice’ consists of two parts. Part 1 contains the detailed statutory requirements. Part 2 (this standard) is a workbook which the carrier can use in practice when implementing the requirements of the Guide to Good Practice.

By applying this Code of Practice, Dutch companies demonstrate compliance with the requirements of Regulation (EC) no. 852/2004, Regulation (EC) no. 853/2004 and Regulation (EC) no. 183/2005.

In the context of GMP+ certification, the responsibility of the carrier undertaking the inland waterway transport is limited solely to (the service of) the inland waterway transport of feed.

| International framework In various paragraphs/ HACCP Work Plans a number of typically Dutch/ European requirements are translated to internationally applicable requirements. |

1.1. Scope and Application of this document

The scope covers:

- All transport of: feed by ship via inland waterways, regardless of whether the transport takes place via an inland waterway vessel or a coastal vessel.

The scope does not cover:

- Transport that is not carried out via inland waterways. The ship is then considered a sea-going vessel. The GMP+ Feed Certification scheme has no requirements for the certification of transport by seagoing vessel.

- Activities with feed, other than transporting the feed by ship via inland waterways (for example storage and transshipment, affreightment). It may be necessary to apply a different GMP+ scope instead of, or in addition to, this document. For the exact details, see F 0.3 Scopes for certification.

The carrier must ensure that the safety of the feed products and services, covered under GMP+ certification, is not negatively affected by (feed and non-feed related) activities, processes, products or services which are not covered under the scope of GMP+ certification.

Control measures, based on a HACCP analyses, must be implemented and monitored to ensure this. All activities potentially influencing feed safety must be available for inspection / auditing.

For the sake of legibility of this document reference will only be made to inland waterway shipping.

This refers to both inland waterway transport and transport by coastal shipping. Unless one of the two modes of transport is explicitly being referred to: then the terms “inland waterway transport” or “short sea shipping transport” will be used.

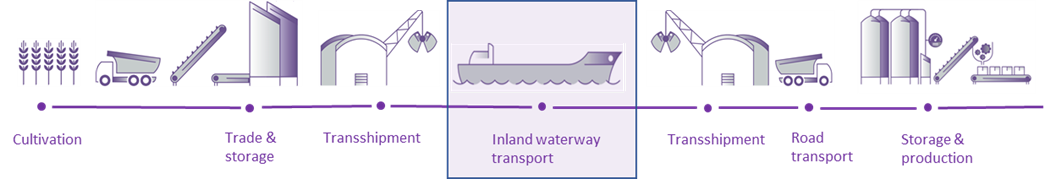

Inland waterway transport of food and feed

The requirements of this document apply to organisations, irrespective of their type or size, with activities which are covered within the scope of this document. It is not important whether these activities are on own account or as a (sub)contractor (‘service provider’).

Each carrier must identify, analyse and control the company specific feed safety hazards by applying HACCP principles. This document describes - as accurately as possible for activities or feed which are covered within the scope of this document , what the requirements are with respect to the various risks, and explains the associated control measures. A carrier may make these control measures part of a prerequisites programme, or may implement them as specific measures for controlling a particular Critical Control Point.

This standard also provides requirements for inspections and audits.

1.2. The structure of this document

This document is structured in a specific way. Chapters 1 and 2 contain more general information. Chapter 3 consists of part two of the Dutch “Inland Waterways Guide to Good Practice”. It also includes work plans, which a carrier must apply to demonstrate that he/she meets the requirements.

| International framework In chapter 3, read “Inland Waterways Guide to Good Practice” as TS 3.3. |

For the explanatory list of relevant terms and definitions see F 0.2 Definition list.

1.3. Exclusion of requirements

It is possible that certain requirements do not apply to a GMP+ certified company. A certified company may exclude these requirements. Exclusions must, however, be justified and recorded. The exclusions may, in any event, not lead to the participant supplying feed/food or offering services which do not comply with safety as defined in the GMP+ FSA Module.

Requirements may not be excluded because the certified company does not con-sider them to be relevant. For example, because customers do not ask for them, or because compliance with these requirements is not a legal obligation; or because the certified company considers itself too small.

1.4. Rules for certification

Within the framework of TS 3.3 inspection, the inspector must verify if the loading compartment is in good technical condition and made of suitable materials which can be effectively cleaned and maintained to avoid contamination of food and feed. For this reason, for an inspection under GMP+ Short Sea Shipping and Inland Waterways Transport, a loading compartment must be empty before assessment.

1.5. Positive declaration

The certified carrier that delivers services of physical transport assured under this GMP+ standard, must report the status of delivered services to the customer in writing. See TS 1.8 Labelling for specific requirements regarding delivery of services.

Helpful tip

The affreightment company plays an essential role in the information exchange between the company that gives the order to transport feed (producer/trader) and the carrier (shipper). For this reason, the positive declaration of the carrier can be a part of the affreightment agreement signed per trip by the carrier, the affreightment company and the company that gives the order to transport feed.

2. What is HACCP

The HACCP system is a major foundation for this standard. HACCP stands for Hazard Analysis and Critical Control Points. In plain language this means: analyse the hazards for feed and food safety and control those hazards. Control means in this case that hazards are prevented or eliminated or are limited to an acceptable degree. Feed and food safety must be assured from cultivation to delivery to the consumer. Including during transportation by inland waterway vessel.

HACCP is part of the European Food Hygiene Regulation and the Feed Hygiene Regulation and has been included in the national legislation. This European Directive and the national legislation offer the possibility to draw up guides related to the safe handling of feed and food. These guides are intended for a complete sector or industry and are based on the principles of HACCP. The guides will be approved by the Government.

The HACCP obligation applies to every company which prepares, processes, handles, packages, transports, stores or transships, distributes or trades the above-mentioned products. Transport by inland waterway vessel also falls under this. The company makes its own decision about whether it works in accordance with an approved guide or sets up its own HACCP system. The Government is tasked with supervision in all cases.

The HACCP system is an feed and food safety system intended to assure feed and food safety. The system must systematically trace, remove or safely control the hazards. The responsibility of the carrier is limited to the transport of the batches involved. The client is also obliged to ensure safe transport of the above-mentioned products. The carrier will therefore require from him that a certified (ISO 17020 or equivalent) control organisation or own loading inspector of the company which issues the order for the transport is appointed to inspect the agreed guidelines of the Guide to Good Practice. For definition see F 0.2 Definition list.

What does it mean that there must be an examination of the hazards for feed and food safety?

As a start, the HACCP system demands an analysis of the hazards and the risks (Hazard Analysis) to feed and food safety which may occur in the event of transportation of the above-mentioned products.

The consumer is the focus of this. The product to be consumed must be safe. The use of contaminated or spoilage products can have serious consequences to public health and may lead to the carrier being held liable.

The danger of contamination and spoilage can be sub-divided into:

- Contamination: contamination due to the loading of different products together

- Contamination due to transport rotation: Transporting different products after one another

- Environment contamination: Contamination and spoilage due to unsatisfactory cleaning or maintenance, walking through the load, bird droppings, weather conditions (rain, snow), etc.

- Temperature rise: Spoilage due to heating up during transport as a result of overheating, faulty refrigeration, etc.

When analysing the above hazards attention must be given to three sorts of hazard namely microbiological, chemical and physical hazards. Some examples are:

- The presence of cleaning materials or chemical agents in the product being transported. For example because of the cleaning of the load compartments (cleaning water left behind) or through contamination by previous loads. This means that the loading compartment must be thoroughly inspected after every load and cleaned if necessary (corrective action). After each cleaning there should be a new inspection and each approval should be recorded in a form (Work Plan 2). Job instructions should be drawn up for the cleaning (Work Plan 5a, 5b, 5c) indicating precisely how to clean. These activities should be recorded (Work Plan 14).

- A second example is the hazard from pest and the associated process of combating pest (by gassing for example). The storage temperature of certain goods may also, for example, form a hazard (growth of pathogenic micro-organisms). The corrective actions for this may be gassing (with a ‘gas-free declaration’) and the inspection and auditing of the environment (temperature, presence of pest).

The hazard analysis examines what the hazards are during the time when the carrier is responsible for the load. This is achieved by tracing and recording any possible hazards during the process of transshipment and transport. The hazard analysis for transportation by inland waterway vessel is part of the work plans of the Work Book of the Inland Waterway Guide to Good Practice. This analysis has already been carried out so that when using the Guide to Good Practice only the steps indicated in the guide have to be followed.

What are critical control points?

Critical control points are actions or process steps at which a hazard may occur for feed or food safety (for example not cleaning a load compartment properly). Once it has been determined where the critical points are located an assessment must be made of whether the established hazards to feed and food safety can be removed or controlled.

Firstly an attempt is made to prevent or remove these hazards. If this is not successful then control measures are used to reduce the hazard to an acceptable level. In all cases there is a ‘Critical Control Point’ (CCP).

The control of the process of transshipment and transport must be done per section via the established critical points. It will have to be established where the critical control points are located and which preventive actions must be taken. It must then be ensured that the process of transshipment and transport is controlled and can, if necessary, be adjusted. All the data must, of course, be recorded and documented.

A number of control measures are established during the whole transport process. These are all specified in the Work Plans 6, 7 and 8.

3. Work plans

3.1. Introduction

Feed and food are especially sensitive to contamination and pollution. The health of the consumer is at risk if products are not transported responsibly and hygienically. This chapter describes how products should be handled during loading and unloading.

Important general requirements are:

- Products may not be contaminated from outside (contamination by another load or contamination by a previous load).

- Products may not be put into a state where an unsafe situation may arise for feed or food (incorrect environment or incorrect temperature).

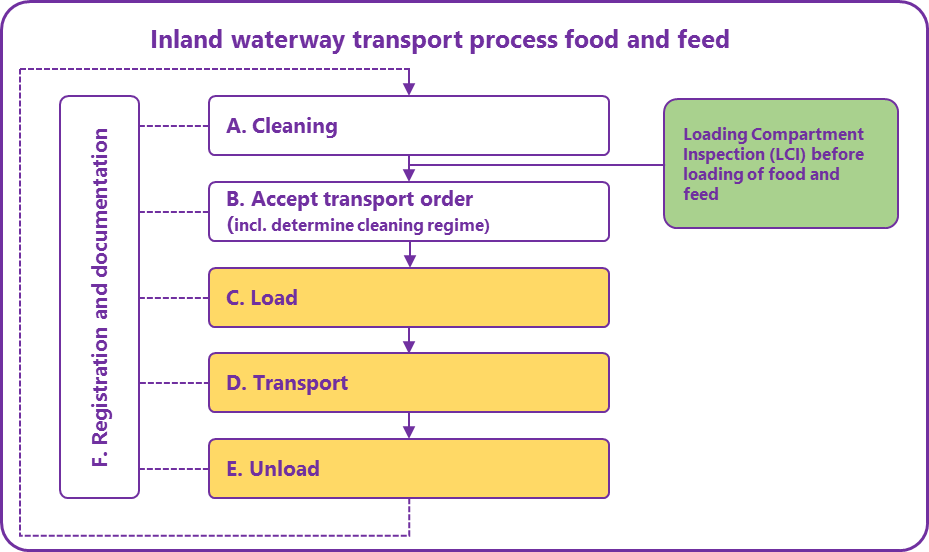

The work plans include the procedures which must be followed. A work plan has been drawn up for every situation. The work plans are sub-divided into three parts: prevention, control and registration.

Please note:

The mentioned work plans show which data must be recorded in writing. The carrier is allowed to use its own format of these work plans as long as all required data are recorded.

The transport process is simple and is as follows:

Three principles apply to the transport of food and feed:

1. Prevent contamination through prevention

2. Work properly by controlling the process

3. Good administration through registration

3.2. Prevention

How is feed and food safety assured during the transport process?

The Inland Waterways Guide to Good Practice is based on the use of work plans. In the structure of these work plans account has been taken of three types of vessel namely tanker vessels (mainly for liquid loads), dry-loading vessels and container vessels. The work plan to be used depends on the load. A distinction is made in the work plans between dedicated transport and non-dedicated transport. Dedicated transport means that the vessel is only used for the transport of food or food and feed. A number of hazards have been eliminated in advance in the event of dedicated transport.

As already stated in the introduction, a critical control point is a point at which a hazard for feed and food safety may occur and where control is necessary to prevent, eliminate or to control this hazard. All critical points which may occur in the transport process are included in the control and prevention items in the Guide to Good Practice work plans. If these work plans are used properly then feed and food safety is assured during the transport of the above-mentioned products.

Basic requirements:

The carrier must ensure that the vessel:

- is made of suitable materials which can be effectively cleaned and maintained to avoid contamination of food and feed. This applies in particular to materials and surfaces which come into direct contact with food and/or feed;

- is in good technical condition;

- is in possession of proper facilities for the collection and storage of waste;

- is suitable for its intended use and functions in accordance with its intended use;

- makes good hygiene production and practices possible;

Moreover, the carrier makes sure that:

- preventive actions are taken against pest and. in the event of an actual pest problem, that a suitable pest control plan is drawn up and implemented;

- employees follow the instructions for general and personal hygiene;

- the loading compartments are clean, fully emptied, free of load remains and free of the odour of prior loads;

- the loading compartments are dry and/or dried in the event of dry subsequent loads;

- the loading compartments are covered, in as far as this does not harm the quality of the product.

Work Plan 1 - Dedicated transport

The first work plan is a work plan in which the possibility of dedicated transport is described. This means that the vessel involved transports either only food or only food, feed materials, compound feed and premixtures. If this vessel does not yet have this status but wishes to be eligible for it then the vessel should be shown to be suitable for dedicated transport by way of an external audit or inspection. In that, pay attention to the specific differences between tank transport and transport of dry cargo. Work Plan 1 is a statement that must be present on the vessel and which must be shown at the request of the auditing bodies.

Work Plan 2 – Loading Compartment Inspection (LCI)

Loading compartments should be constructed such that they can be cleaned properly and regularly. These compartments should be of good quality and well maintained. Pets and pest should be prevented from contaminating the products. When inspecting these loading compartments in advance use is made of Work Plan 2 (load registration form). The inland waterway carrier has the duty to report his previous loads on this form.

The principal or the owner of the goods will have the loading compartments inspected before loading by an control organisation certified (ISO 17020 or equivalent) for that purpose or own loading inspector of the company which issues the order for the transport (manufacturer and/or trader).

Control organisation : company accredited in accordance with ISO 17020 with a specialisation in feed or grains or liquid agri-bulk and/or internationally operating in accordance with a recognised certification system such as ISO 9001: 2015 where the inspection of loading compartments is demonstrable mentioned as a part of the certified scope.

Own loading inspector : a loading inspector employed by a GMP+ certified participant. This is a position which is held by an employee who on the basis of training and experience has the knowledge and expertise to be able to inspect the load compartment for its suitability for loading with feed.

It is a legal obligation that this work plan is used and recorded for each load of food or feed. The carrier should of course meet the (additional) requirements set by the principal.

Work Plans 3, 4 and 5 - Hygiene and Cleaning

Requirements are set not only on the products themselves with respect to hygiene but also on the people who handle the products. They may come into contact with raw materials, semi-manufactured goods and end products and may therefore be a major source of contamination with micro-organisms. The carrier should ensure that the necessary hygiene and safety is taken into consideration on board.

Breakable attributes (for example glass) may not be used. Two work plans have been drawn up for hygiene on board namely Work Plan 3 (personal hygiene) and Work Plan 4 (general hygiene).

The loading compartments must be cleaned in accordance with the instructions (for feed see Work Plan 9b). Registration of the cleaning takes place in accordance with Work Plan 14.

The material (such as materials used for sampling) which comes in contact with the products or which could do so must also be regularly cleaned. Cleaning agents and disinfectants should be so-called ‘food grade’ products. Work Plan 5a, 5b, 5c has been drawn up for the cleaning of loading compartments. Cleaning is a CCP.

Food grade: these are safe cleaning and / or disinfecting agents that can be used in the transport of products intended for the feed and / or food industry. The user should check this on the instructions for use of the product.

3.3. Control

How is feed and food safety made controllable during the transport process?

Work Plans 6, 7 and 8 - Loading, transporting and unloading

The products should be transhipped and transported in such a way that pollution and contamination is avoided. As stated above, the transport process consists of three steps where each step has specific critical control points. These critical control points are sufficiently controlled if they are properly controlled and registered. The following work plans indicate where the control points are located and they must be controlled. These plans are Work Plan 6 (loading), Work Plan 7 (transport) and Work Plan 8 (unloading). Contamination as a result of precipitation during loading and unloading is a CCP.

Work Plans 9 and 10 – Previous loads and prescribed temperatures

The established norms and limit values should be adhered to and account should be taken of the usual rejection limits as laid down in laws and contracts. Contamination from the outside (for example from another load) and damage caused by the product itself (for example due to incorrect temperatures) must be prevented. The following plans have been drawn up for this: Work Plan 9a, 9b, 9c , (preparation of dedicated status and working with forbidden and unlisted loads), and Work Plan 10a, 10b, 10c (prescribed temperatures). Temperature recording is a CCP.

Work Plan 11 - Cargo Record Book

The carrier is responsible for the registration of the loads. Registration can take place in a cargo record book. Transported loads can be effectively traced through the registration of loads and any particular details. Work Plan 11 contains an example of a loading journal.

Work Plan 12 – Protest letter

The carrier is responsible for any contamination of the goods which may mean a hazard to feed or food safety during transport. The carrier may submit a protest if there are no expert auditors available and make this known to his clients. Work Plan 12 is an example of such a protest letter.

Work Plan 13 – Handling complaints

The carrier is responsible for the corrective actions to be taken in the event of non-conformities. The corrective actions are specified in Work Plans 6, 7 + 8. A major part of the corrective actions is the handling of both internal and external complaints. The complaints can be processed by using a complaints registration form Use is made in the Guide to Good Practice of a complaints registration form. Work Plan 13 is an example of a complaint registration form.

3.4. Registration

How is feed and food safety registered and verified during the transport process?

The areas of responsibility must be described. All agreements must also be recorded in writing. With respect to transport by inland waterway, the carrier is responsible for the safe transport of the feed and food goods. All documentation is recorded in accordance with the work plans 14 and 15 (registration, documentation and verification). Work Plan 16 handles the after-care of the system. Control of the total system is assured if the carrier makes records in accordance with all the procedures and instructions in the Inland Waterway Guide to Good Practice.

Work Plan 14 – Registration and documentation

All data should be recorded in writing partly in connection with proper traceability. In addition there must be instructions available at the work site which describe how action is to be taken. Work Plan 2 (inspection of loading compartments), Work Plan 13 (sampling of products) and Work Plan 13 (quality improvement form) are the main documents to be registered. Registration is a legal obligation of which you will in contravention if you do not carry it out. The procedure for registration and documentation has been laid down in Work Plan 14 .

Work Plan 15 – Verification

Verification is checking to see if the Guide is being complied with. The operation of the Guide must be verified regularly. Inspection is used to find out if the system is working as intended. Recording can be done by keeping the reports drawn up in accordance with the specified inspection in Work Plan 15 .

This work plan can be an additional part of an external verifier.

Work Plan 16 – After-Care

This last step ensures that in the event of changes to the product to be transported or in the event of changes to the transportation process, the system can be modified. The inspection in Work Plan 15 provides for irregularities within the Guide to Good Practice. All changes which relate to feed and food safety (such as legal provisions) will be recorded by the organisation of interested parties. These changes to the Guide to Good Practice will then be sent round to all carriers which use this code. The procedure for changing the procedures and instructions in the Guide to Good Practice has been laid down in Work Plan 16 .

3.5. Overview of work plans

Work Plan 1 - Dedicated transport

General information on the product groups which are transported and any determination of ‘dedicated transport’.

Work Plan 2 - Loading Compartment Inspection (LCI)

Information & Inspection relating to the product and the loading compartments (form)

Work Plan 3 - Personal hygiene

General instructions related to personal hygiene on board

Work Plan 4 - General hygiene

General procedure for hygienic working on board

Work Plan 5 - Cleaning

General cleaning procedure for loading compartments

Work Plan 6 - Loading

General procedure for loading

Work Plan 7 - Transport

General procedure for transportation

Work Plan 8 - Unloading

General procedure for unloading

Work Plan 9 - Previous Loads

Procedure for obtaining “dedicated” status and what to do with forbidden and unlisted loads

Work Plan 10 - Prescribed temperatures

Procedure for minimum & maximum temperatures of the load

Work Plan 11 - Cargo Record Book

Registration for loads

Work Plan 12 - Protest Letter

Procedure for submitting a protest

W ork Plan 13 - Complaints handling

Procedure for complaints handling

Work Plan 14 - Registration and documentation

Procedure for registration and documentation

Work Plan 15 - Verification

Verification procedure

Work Plan 16 - After-Care

Procedure relating to changes to the Guide to Good Practice

HACCP WORK PLAN 1a Food

AIM: To provide information on the products to be transported which may lead to the determination of possible hazards, recognise those hazards and prevent any contamination. The exclusive transportation of food or raw materials for food leads to ‘dedicated’ transport.

SPECIALISATIONS:

- TRANSPORT BY DRY LOAD SHIP (INLAND WATERWAY)

- TRANSPORT BY TANKER (INLAND WATERWAY)

VESSEL NAME : ………………………………………………………………………………….

SHIPPER : ………………………………………………………………………………….

DECLARATION :

- THAT THE ABOVE-MENTIONED VESSEL, AFTER A THOROUGH CLEANING AND EXPERT INSPECTION, (for more than 6 months on a very regular basis meaning at least several times per month) ONLY TRANSPORTS THOSE PRODUCTS DESCRIBED BELOW AND THEREFORE IS ELIGIBLE FOR THE DESIGNATION:

- THAT THE ABOVE-MENTIONED TANKER WAS ORIGINALLY BUILT OR SUFFICIENTLY CONVERTED FOR THE TRANSPORT OF THOSE PRODUCTS DESCRIBED BELOW AND THEREFORE ELIGIBLE FOR THE DESIGNATION:

'FOOD ONLY'

or words with a similar meaning

PRODUCTS : IN PRINCIPLE ALL FOOD AND RAW MATERIALS FOR FOOD IN BULK LOADS BOTH IN LIQUID FORM AND IN SOLID FORM WITH THE EXCEPTION OF WHOLE LOADS OF ADDITIVES OR OTHER PRODUCTS WHICH ARE ADDED TO FOOD ONLY IN VERY SMALL PERCENTAGES.

PRODUCT NAMES : …………………………………………………………………………..............………………………………………………………………………………………………………………

SHIPPER/OWNER

(stamp + name + signature)

……………………………………....

CONTROL ORGANISATION

(stamp + name + signature)

…………………..………..............

HACCP WORK PLAN 1b Feed

PRODUCTS AND PRODUCT GROUPS

AIM: To provide information on the products to be transported which may lead to the determination of possible hazards, recognise those hazards and prevent any contamination. The exclusive transportation of feed materials, compound feed and premixtures leads to ‘dedicated’ transport.

SPECIALISATIONS:

- TRANSPORT BY DRY LOAD SHIP (INLAND WATERWAY

- TRANSPORT BY TANKER (INLAND WATERWAY)

VESSEL NAME : ………………………………………………………………………………….

SHIPPER : ………………………………………………………………………………….

DECLARATION :

- THAT THE ABOVE-MENTIONED VESSEL, AFTER A THOROUGH CLEANING AND EXPERT INSPECTION, (for more than 6 months on a regular basis) ONLY TRANSPORTS THOSE PRODUCTS DESCRIBED BELOW AND THEREFORE IS ELIGIBLE FOR THE DESIGNATION:

- THAT THE ABOVE-MENTIONED TANKER WAS ORIGINALLY BUILT OR SUFFICIENTLY CONVERTED FOR THE TRANSPORT OF THOSE PRODUCTS DESCRIBED BELOW AND THEREFORE ELIGIBLE FOR THE DESIGNATION:

'FEED ONLY, AGRI-ONLY

or words with a similar meaning

PRODUCTS : IN PRINCIPLE ALL FEED MATERIALS, COMPOUND FEED AND PREMIXTURES IN BULK LOADS BOTH IN LIQUID FORM AND IN SOLID FORM WITH THE EXCEPTION OF WHOLE LOADS OF ADDITIVES OR OTHER PRODUCTS WHICH ARE ADDED TO FEED ONLY IN VERY SMALL PERCENTAGES.

PRODUCT NAMES :

…………………………………………………………………………..............………………………………………………………………………………………………………………

SHIPPER/OWNER

(stamp + name + signature)

…………………..………..............

CONTROL ORGANISATION

(stamp + name + signature)

……………………………………....

HACCP WORK PLAN 2

LCI (Loading Compartment Inspection)

(Example provided that all relevant information listed below must be included)

AIM: Establishing possible hazards by obtaining information & carrying out inspections of the state of the loading compartments and ensuring that these hazards are recognised and eliminated.

| No / REFERENCE : | |

| ||

| INSTRUCTING PARTY : | | |||

| NAME BARGE / TELEF. : | | |||

| PLACE OF INSPECTION : | | DESTINATION : | | |

| INTENDED TO LOAD KG : | | PRODUCT : | | |

| TEMPERATURE (if applicable) : | ||||

| | ||||

| DATE OF INSPECTION : | STARTED : | COMPLETED : | ||

| | GMP+-ALLOWED | |||||

| PREVIOUS CARGOES* : | LAST / Laatste / Dernier | | YES | NO | ||

| 2ND / 2de / 2ème | | YES | NO | |||

| 3RD / 3e / 3ème | | YES | NO | |||

| CLEANING : | DRY / droog / sec | YES | NO | |||

| WITH WATER / met water / à l' eau | YES | NO | ||||

| WATER + DETERGENT / water + detergent / eau + détergent | YES | NO | ||||

| WATER + DETERGENT + DESINFECTION | YES | NO | ||||

| | ||||||

| RESULTS : | EMPTY / Leeg / Vide | YES | NO | |||

| CLEAN / Zuiver / Propre | YES | NO | ||||

| DRY / Droog / Sec | YES | NO | ||||

| FREE FROM ODOUR / Geurloos / Sans odeur | YES | NO | ||||

| FREE FROM INSECTS / Vrij van ongedierte / Exempt de pest | YES | NO | ||||

| FREE FROM REMNANTS OF PREVIOUS CARGOES / Vrij van vorige ladingresten / Sans restes de chargements antérieurs | YES | NO | ||||

| VISUAL : TOTALLY INTACT AND FULLY CLOSING | YES | NO | ||||

| TYPE OF HEATING (tankers): steam / hot water / thermal oil | ||||||

| FINAL RESULT : | ACCEPTED FOR LOADING | YES | NO | |||

| REMARKS / Opmerkingen / | | |||||

| SURVEYOR'S NAME : Le controleur : | | THE CAPTAIN : | | |||

* the last three bulk loads (last, penultimate, third last), stating the interim other non-bulk loads and possibly the mention agri-only.

HACCP WORK PLAN 3

PERSONAL HYGIENE ON BOARD

AIM: Through personal hygiene on board preventing any harmful influence on the feed or food safety of the products to be transported.

The following procedure applies for personal hygiene on board:

- Both the carrier and his personnel must be aware of the legislation relating to personal hygiene during the loading, transport and unloading of feed and food;

- The carrier must supervise his personnel and any third parties during their activities on board.

- Personal hygiene on board means:

- Persons who suffer from the following complaints must immediately report the complaint and the possible cause to the carrier and must not come into contact with the load. This is especially true for:

- an illness which is transferred via food.

- infected wounds, skin infections or sores

- diarrhoea, vomiting, jaundice.

- It is not permitted to eat, smoke or drink in loading compartments for food or feed.

- During the loading or unloading of bulk goods it is not permitted to eat, smoke or drink.

- Personnel who come into contact with food or feed will wear clean portative clothing, head covering and footwear. Clean footwear (overshoes) when entering the load.

- Personnel (such as inspectors) who come into contact with food or feed must take measures to prevent the contamination of food or feed by personal possessions or jewellery (pens, pencils, GSM, lighters, cigarettes, earrings, rings, etc.).

HACCP WORK PLAN 4

GENERAL HYGIENE PROCEDURE

AIM: To prevent any harmful influence on the feed or food safety of the products to be transported.

The following procedure applies for hygiene on board:

- Both the carrier and his personnel must be aware of the legislation relating to hygienic working during loading, transport and unloading of the goods;

- The carrier must supervise his personnel during their activities on board.

- The carrier will take suitable preventive actions against pest on board. The carrier will therefore ensure

- Well-maintained loading compartments and seals (valves, hatches);

- The proper discharge of flushing and rainwater, not accessible to rodents

- A clean working environment, free of dirt, food and places to hide for rodents;

- A good, hygienic method of working, and

- A good entry check (within the possibilities available to the carrier).

In the case of an actual pest problem (anywhere on the ship), the carrier will ensure that a certified pest controller draws up a suitable control plan and / or a certified company can gas the contaminated spaces against harmful insects. The presence of pest in the cargo must be reported to the client.

- Hygienic working on board means the prevention of:

- Accumulation of dirt in the loading compartments,

- Contamination created by previous loads,

- Contamination created by joint loads,

- Mould in the loading compartments,

- Contamination with oil or water from other compartments or ballast water,

- Faults on board the vessel such as cracks and holes through which pest or flushing water and suchlike can enter.

- Contamination created by the cleaning, pesticide and disinfectants used.

- Pets get into loading compartments in which there are food or feed stored.

- External contamination during loading and unloading (weather, birds, bird excretions etc.)

HACCP WORK PLAN 5a

GENERAL CLEANING PROCEDURE FOR TANKER VESSELS

AIM: The prevention of possible contamination by components which are undesirable for feed and food through proper, expert cleaning of the loading compartments.

PROCEDURE

The cleaning procedure for the loading tanks of tankers will contain at least the following sections:

- The loading compartments must be completely emptied.

- Loading compartments will be washed with hot or cold water (see provisions under c) depending on the previous load. The following applies:

- cold water is used for products which do not solidify

- hot water is used for products which do solidify.

- The water is sprayed by way of a 'butter wash installation' or similar under high pressure (c. 6 bar), into the loading compartments. This 'washing water' is sucked out using the loading pump and pumped into the 'swill tanks'It is very important that the water used for cleaning means of transport is of good quality (spring water, tap water, process water). In this, it is important that the owner of the means of transport carries out a risk assessment of the (re)use of the washing water. The water must be of such quality that it cannot cause contamination on the product to be loaded. The carrier can carry out (source) water analysis (or have it carried out) or request analysis results from the water supplier of the washing water. Any cargo residues must be disposed of in accordance with the rules of the Scheepsafvalstoffenbesluit (Ship Waste Decree) and the CDNI Convention.

| International framework Any cargo residues must be disposed of in accordance with the rules of the local competent authority. |

- Only food grade' cleaning agents may be used. The carrier must be able to demonstrate this by technical data sheets (for example MSDS - Material Safety Data Sheets). Data sheets are available from the suppliers of the cleaning agents..

- After cleaning, there may be no detectable traces of the cleaning agents left in the loading compartment and the pipes (odour, foam, moisture etc.).

- The cleaning which is carried out must be recorded.

- There should always be an inspection of the loading compartments (LCI) after cleaning and before loading with food or feed. This must be done by a certified control organisation

- ISO 17020 or equivalent or competent person of the company which issues the order for the transport (manufacturer and/or trader).

For definition see F 0.2 Definition list. This is a legal obligation for the load owner (principal). If no LCI takes place, the skipper must draw up a protest letter (WP 13) and send it to the principal.

Deviations from these rules are carried out by order and in consultation with the load stakeholders, but may never lead to a lower form of cleaning than prescribed in this standard.

NOTE

In the event that a carrier receives a report of a microbiological deviation in a previous batch then the loading compartment must also be disinfected with a food grade disinfectant during the next cleaning. The carrier must be able to demonstrate this by technical data sheets (for example MSDS). Disinfection always takes place after cleaning. No traces of disinfectant may remain after disinfection.

HACCP WORK PLAN 5b

GENERAL CLEANING PROCEDURE FOR DRY LOADING VESSELS

AIM: The prevention of possible contamination by components which are undesirable for feed and food through proper, expert cleaning of the loading compartments.

PROCEDURE

The cleaning procedure for the loading tanks of dry-loading vessels will contain at least the following sections:

- The loading compartments must be completely emptied.

- Depending on the previous load the loading compartments will be handed over brushed clean.

- The brooms, scoops, etc. used for cleaning the loading compartments must be cleaned after use. This cleaning must be registered. This is especially true if the brooms, scoops, etc. are also used for other loads than food and feed.

- Depending on the previous load the loading compartments will be cleaned with detergent and/or sprayed with water. Washing water and any load residues must be disposed of in accordance with the rules of the Ship Waste Decree and the CDNI Convention.

| International framework Any cargo residues must be disposed of in accordance with the rules of the local competent authority. |

- Only 'food grade' cleaning agents may be used. The carrier must be able to demonstrate this by technical data sheets (for example MSDS). Datasheets can be requested from the supplier.

- After cleaning, there may be no detectable traces of the cleaning agents left in the loading compartment (odour, foam, moisture etc.).

- If the loading compartments are dry then the vessel is ready for a new load.

- The cleaning which is carried out must be recorded.

- There should always be an inspection of the loading compartments (LCI) after cleaning and before loading with food or feed. This must be done by a certified control organisation

(ISO 17020 or equivalent) or competent person of the company which issues the order for the transport (manufacturer and/or trader). For definition see F 0.2 Definition list. This is a legal obligation for the load owner (principal). If no LCI is carried out, the skipper must draw up a protest letter (WP 13) and send it to the principal.

Deviations from these rules are carried out on behalf of and in consultation with the load stakeholders, but may never lead to a lower form of cleaning than prescribed in this Guide to Good Practice.

NOTE

In the event that a carrier receives a report of a microbiological deviation in a previous batch then the loading compartment must also be disinfected with a food grade disinfectant during the next cleaning. The carrier must be able to demonstrate this by technical data sheets (for example MSDS). Disinfection always takes place after cleaning. No traces of disinfectant may remain after disinfection.

HACCP WORK PLAN 5c

GENERAL CLEANING PROCEDURE FOR CONTAINER AND GENERAL CARGO VESSELS

AIM: The prevention of possible contamination by components which are undesirable for feed and food through proper, expert cleaning of the loading compartments (containers and general cargo).

PROCEDURE

As the containers are received and delivered filled and closed, there is no cleaning procedure which applies to the transportation of containers.

Packaged general cargo (boxes, bagged goods, IBCs, etc.) ensures to a greater or lesser degree that there is protection from the outside world. After packaged general load (regardless of the type of load), the loading compartment hold should be cleaned with water at least. This in connection with packaging residues (paper, wood splinters, metal splinters, pieces of rope, jute, etc.) that may remain behind.

Deviations from these rules will take place at the behest of and in consultation with those with an interest in the load, but can never lead to a lower form of cleaning than prescribed in this standard.

HACCP WORK PLAN 6

HACCP- PLAN FOR "CLEANING, ACCEPTANCE OF THE ORDER AND LOADING"

AIM: To ensure by way of audits and corrective actions that no contamination by components which may be harmful to feed or food can take place.

| SBM Number (process) | Risk | Norms | Control measure | Control | Corrective action | Documentation - Work Plan | ||||

| Action limit | Rejection limit | | Method | Frequency | Responsibility | Method | Responsibility | |||

| SBM1 (Cleaning) | Unsatisfactory cleaning with as a result: | Traces (visual, odour) of previous load, dry floors in loading compartments. | Cleaning and, if necessary, disinfection of loading compartment and loading equipment and tools in accordance with the Appendix 1. | Organoleptic (visual, odour) check of loading compartment and loading equipment | After every cleaning | Carrier, Inland waterway transport staff | Clean again, possibly extend cleaning (with water, food grade cleaning agent) and check again. | Carrier | Work Plan 5a, 5b and 5c,Appendix 1 | |

| - Microbial contamination | Salmonella absent in 25g. | |||||||||

| - Physical contamination | - No demonstrable traces of glass, metals, plastic - Botanical purity (feed) min. 95% - Contractual agreements | Inspection of the cleaning of critical components. | After every cleaning | Carrier, Inland waterway transport staff | Clean again, possibly extend cleaning (with water, food grade cleaning agent) and check again. Revise cleaning plan in the event of repeated non-conformity. | Carrier | ||||

| - Chemical contamination | In accordance with legal norms. | LCI | Before every load | Inspector | Clean again, possibly more extensively and resubmit the loading compartment for inspection. No inspector present: inform the principal via protest letter | Carrier | ||||

| “Dedicated” transport | Check freights for last 6 months. | Once on inspection request | Inspector | From last “non-dedicated” load, set new period of 6 months for fresh inspection. | Carrier | |||||

| SBM2 (Loading) | Non-standard temperature with as result: | In accordance with temperature overviews Work Plan 10a, 10b, 10c. | - Measure, compare and record temperature on receipt.** - Organoleptic check (colour, structure, odour)* | Comparison to standard value Compare product to recorded batch details | Every relevant load | Carrier, Inland waterway transport staff | - Stop loading - Inform client - Follow-up action in consultation with client. - pest control - comment in loading journal | Carrier | ||

| - Physical deviations (colour, odour, viscosity) | - In accordance with product characteristics in the specification. - Pumpability (fats and oils) | |||||||||

| - Microbiological growth | Salmonella absent in 25g. | |||||||||

| SBM3 (Loading / Unloading) | Precipitation during loading or unloading with the risk of: | | Protect loading compartment and load against precipitation | Supervision of the best possible sealing of the loading/unloading opening and of the loading compartment. | For any form of precipitation | Inland waterway transport staff | - Statement by owner questions - Stop loading / unloading - Note in cargo record book - Inform client - Follow-up action in consultation with client. - Block load | Carrier | ||

| | - Physical damage (increased moisture content, damage to packaging) | No external traces of damage to products or packaging | ||||||||

| | - Microbiological growth | Salmonella absent in 25g. | Visual assessment of “rained on” batch for mould or condensation* | During delivery of batches where loading took place during precipitation | Carrier Inland waterway transport staff | |||||

* Check during unloading and of the unloading equipment and the general state of hygiene of the unloading location by the shipper is necessary but always within the possibilities available to the shipper. The client or owner or recipient is responsible for the unloading equipment involved.

HACCP WORK PLAN 7

HACCP PLAN for "TRANSPORT"

AIM: To ensure by way of audits and corrective actions that no contamination by components which may be harmful to feed or food can take place.

| SBM Number (process) | Risk | Norms | Control measure | Control | Corrective action | Documentation - Work Plan | |||

| SBM4 (Transport) | Temperature variations due to fault in refrigeration equipment with as a result: | | Properly functioning refrigeration equipment | - Measurement of the temperature of the load involved (temperature must be readable from the outside). | Daily for refrigerated batches. Registration in cargo record book | Carrier Inland waterway tranort staff | - Block load - Note in cargo record book - Inform client - Follow-up action in consultation with client. | Carrier | |

| - Physical damage (structure damage, colour or odour deviations, packaging damage) | No traces of organoleptic deviations in load.* | ||||||||

| - Microbiological growth | Salmonella absent in 25g. | - Check operation of refrigeration equipment | Vessel refrigeration: monthly | Carrier | - Inform client - In consultation, transfer load to another vessel - Note in cargo record book - Repair equipment - Possibly switch to emergency arrangements. | ||||

| Refrigerated container (reefer): during loading | Carrier Inland waterway transport staff | - Inform client - In consultation, transfer load to another container. - Note in cargo record book - Possibly switch to emergency arrangements. | |||||||

* Check must take place with the possibilities available to the shipper.

HACCP WORK PLAN 8

HACCP PLAN for "UNLOADING"

AIM: To ensure by way of audits and corrective actions that no contamination by components which may be harmful to feed or food can take place.

| SBM Number (process) | Risk | Norms | Control measure | Control | Corrective action | Documentation - Work Plan | |||

| SBM3 (Loading / Unloading) | Precipitation during loading or unloading with the risk of: | | Protect loading compartment and load against precipitation | Supervision of loading and unloading and the covering of loads and the loading compartment. | For any form of precipitation | Inland waterway transport staff | - Statement by owner questions - Stop loading / unloading - Note in cargo record book - Inform client - Follow-up action in consultation with client. - Block load | Carrier | |

| - Physical damage (increased moisture content, damage to packaging) | No external traces of damage to products or packaging | ||||||||

| - Microbiological growth | Salmonella absent in 25g. | Visual assessment of “rained on” batch for mould or condensation | During delivery of batches where loading took place during precipitation | Carrier Inland waterway transport staff | |||||

* Check during unloading and of the unloading equipment and the general state of hygiene of the unloading location by the shipper is necessary but always within the possibilities available to the shipper.

The client or owner or recipient is responsible for the unloading equipment involved.

HACCP WORK PLAN 9a TANKERS

PREPARATION FOR “DEDICATED FOOD and/or FEED ” STATUS

AIM: To use guidelines to ensure that “dedicated” status can be obtained.

These guidelines apply to inland waterway vessels which wish to comply with the requirements for ‘dedicated food and/or feed’’ transport status in accordance with Work Plan 1a.

- Guideline for products which still have to go through a processing stage:

- Ships equipped with stainless steel loading compartments:

These ships must originally be built for the transport of products for the food and / or feed industry. Should these ships have loaded products other than products for the food and feed industry, all parts that may come into contact with the load must be replaced with stainless steel materials. This applies to the pipes, coils, pumps (and possibly even the loading compartments and the boiler, if these are not in good condition and / or cannot be cleaned properly. This must be substantiated by a specific risk analysis). - Ships equipped with iron (mild steel) or coated loading compartments:

These ships must originally be built for the transport of products for the food and / or feed industry. If these ships have loaded products other than products for the food and feed industry, these ships will no longer be eligible for the status of dedicated food and / or feed, unless all parts that may come into contact with the load (loading compartments, pipes, coils, pumps, boiler, etc.) are replaced by new stainless steel materials.

Please note: This also applies to the mild steel slob tanks and / or mild steel ballast tanks if these are used for washing the cargo tanks.

In all cases, a careful inspection and associated analysis must be carried out by a recognized control organisation (ISO17020) and a maritime expert. After approval, the control organisation issues a release certificate (certificate) and an inspection report from the maritime expert, which is required to obtain the dedicated status. This certificate is not an LCI (visual inspection) but a statement that all the above requirements have been met.

The dedicated status does not release the ship from the usual inspections (LCIs) and the cleaning procedures involved (Appendix 1).

HACCP WORK PLAN 9b DRY LOAD SHIPS

PREPARATION FOR “DEDICATED FOOD and/or FEED” STATUS

AIM: To use guidelines to ensure that “dedicated” status can be obtained.

These guidelines apply to vessels which wish to comply with the requirements for ‘dedicated feed’ transport status in accordance with Work Plan 1b.

- Guideline for products which still have to go through a processing stage (raw material):

- Vessels equipped with stainless steel or properly coated loading compartments:

After thorough cleaning by an expert company (tank cleaning) only neutral products (see Appendix 1) should be transported for the first six months (on a regular basis at least several times a month). - Vessels equipped with iron (mild steel) or wooden loading compartments:

After thorough cleaning by an expert company (tank cleaning) only neutral products (see Appendix 1) should be transported for the first six months (on a regular basis, at least several times a month). After this period, the ship must be sandblasted and repainted (food grade, see explanation paragraph 3.2).

- Vessels equipped with stainless steel or properly coated loading compartments:

- Guideline for products which no longer have to go through a processing stage (finished products):

- Vessels equipped with stainless steel or properly coated loading compartments:

After thorough cleaning by an expert company (tank cleaning) only neutral products of vegetable origin (see Appendix 1) should be transported for the first six months (on a regular basis, at least several times a month). Ships that have transported forbidden loads (such as. household waste) do not qualify for the dedicated status unless they replace the loading compartments.

- Vessels equipped with iron (mild steel) or wooden loading compartments:

All previous loads must have been feed materials, compound feed or premixtures or the vessel should have loading compartments which were built for the transport of feed materials, compound feed or premixtures. If this has been deviated from, the dedicated status cannot be obtained, unless they replace the loading compartments.

In all cases, a careful inspection and associated analysis must be carried out by a recognized control organisation (ISO17020) or equivalent. After approval, this company issues a release certificate, which is required to obtain the dedicated status.

The dedicated status does not release the ship from the usual inspections (LCIs) and the cleaning procedures involved (Appendix 1).

HACCP WORK PLAN 9c DRY LOAD SHIPS

RELEASE AFTER THE TRANSPORT OF FORBIDDEN AND UNLISTED LOADS

AIM: Preventing by way of guidelines the contamination of feed and food by undesirable previous loads.

These guidelines apply to inland waterway vessels which have transported a prohibited or unlisted load and then wish to transport food or feed.

There may be circumstances in which a carrier has transported a forbidden or unlisted load. The usual cleaning procedures (Work Plan 5a, 5b, 5c) are not sufficient in this case for releasing the vessel and the loading compartments for the transport of food and feed.

- If any previous load appears on the list of ‘‘forbidden previous loads’ (see Appendix 1) or is not listed at all, then the vessel is no longer suitable for the transportation of food, feed, compound feed or premixtures and must be removed from the list of accepted ships.

A loading compartment can be released after forbidden loads in accordance with the following procedure:

Step 1

Cleaning in accordance with the forbidden load shall be carried out using water and a food grade cleaning agent and/or a food grade disinfection with a food grade disinfection agent (if applicable) according to the nature of the forbidden load, according to a protocol previously developed by the company. All loads that fall under the scope of EU Regulation 999/2001 must have and follow a procedure approved and documented by the competent authority.

| International framework All loads that fall under the scope of EU Regulation 999/2001 must follow regulations of the relevant local authorities. For the loads falling under the scope of EU Regulation 999/2001 see Forbidden previous loads in Appendix 1 of this document. |

Step 2

Assessment at the expense of the company of the loading area after the above cleaning and disinfection as specified in step 1 by a approved control organisation (ISO 17020 or equivalent). For definition see F 0.2 Definition list.

The control organisation will use a cargo record book to find out which previous loads have been transported and which cleaning and disinfections have been carried out.

The loading area of the means of transport is then organoleptic checked for any residue, especially in places that are difficult to clean. Any further doubt with the verifying body requires further steps to be taken (see note below).

PLEASE NOTE: This inspection goes much further than an LCI. The risks and also liability are many times higher because of the possible adverse effects of the forbidden load. If the doubt cannot be allayed, the loading compartments must be sandblasted and repainted (food grade paint or coating). The certificate of release must ensure that the ship can be used again for food and feed. It is not an inspection certificate, but a guarantee certificate.

Step 3

Issuing by the control organisation of a certificate that must indicate whether the loading area can be released for (further) transport of feed and food.

Note:

Depending on the previous loads and the results of the visual inspection, then, at the discretion of the inspector from the control organisation, further hygiene measurements can be carried out using ATP measurements and/or agar stamps, at the carrier’s expense. Another possibility is rinsing again followed by an analysis of the latest flushing water. In extreme cases, sandblasting and repainting of the loading compartments is the only option.

Appendix 1 includes additional instructions on unlisted loads.

HACCP WORK PLAN 10a

PERMITTED TEMPERATURES IN THE EVENT OF TANKER TRANSPORT

AIM: To protect products which are sensitive to temperature changes from spoilage or other processes which are undesirable for feed or food by way of guidelines.

The CODEX has drawn up the following guidelines with respect to maximum and minimum temperatures for the loading and unloading of batches of edible oils and fats.

CODEX CAC/RCP 36 – 1987 (Rev. 6-2015)

Recommended international guide to good practice for the storage and transport of edible oils and fats in bulk:

| | Storage and bulk transport | Loading and unloading | ||

| Oil / fat | Min ° C | Max ° C | Min ° C | Max ° C |

| Castor Oil | 20 | 25 | 30 | 35 |

| Coconut oil | 27 | 32 | 404 | 454 |

| Fatty acids, coco | Environment | Environment | Environment | Environment |

| Cotton seed oil | Environment | Environment | 20 | 251 |

| Fish oil | 20 | 25 | 25 | 30 |

| Fish fatty acids | Environment | Environment | Environment | Environment |

| Ground nut oil | Environment | Environment | 20 | 251 |

| Hydrogenated oil | Variable | - | Variable | -2 |

| Lipid butter | 38 | 41 | 50 | 55 |

| Pig fat (Lard) | 40 | 45 | 50 | 55 |

| Linseed oil | Environment | Environment | 10 | 201 |

| Corn oil | Environment | Environment | 10 | 201 |

| Olive oil | Environment | Environment | 10 | 201 |

1 It is recognised that in some cases the ambient temperatures may exceed the recommended maximum figures shown in the Table.

2 Hydrogenated oils can vary considerably in their slip melting points, which should always declared. It is recommended that during the voyage, the temperature should be maintained at around the declared melting point and that this should be increased prior to discharge to give a temperature of between 10 and 15oC above that point to effect a clean discharge.

3 Different grades of palm stearin may have wide variations in their slip melting points and the temperature quoted may need to be adjusted to suit specific circumstances.

4 For warmer climates, the loading and discharge temperatures for coconut oil and palm kernel oil are Min 30oC, Max 35oC or ambient temperatures

| | Storage and bulk transport | Loading and unloading | ||

| Oil / fat | Min ° C | Max ° C | Min ° C | Max ° C |

| Palm oil | 32 | 40 | 50 | 55 |

| Palm olein | 25 | 30 | 32 | 35 |

| Palm stearin | 40 | 45 | 60 | 703 |

| Palm fatty acids | Environment | Environment | Environment | Environment |

| Palm kernel oil | 27 | 32 | 404 | 454 |

| Palm kernel olein | 25 | 30 | 30 | 35 |

| Palm kernel stearin | 32 | 38 | 40 | 45 |

| Palm kernel fatty acids | Environment | Environment | Environment | Environment |

| Rape seed oil | Environment | Environment | 10 | 201 |

| Rapeseed fatty acids | ? | ? | ? | ? |

| Safflower oil | Environment | Environment | 10 | 201 |

| Sesame (seed) oil | Environment | Environment | 10 | 201 |

| Sheanut butter | 38 | 41 | 50 | 55 |

| Soybean oil | Environment | Environment | 20 | 251 |

| Soya/Sunflower/Maize fatty acids | Environment | Environment | Environment | Environment |

| Sunflower oil | Environment | Environment | 10 | 251 |

| Cattle / Vegetable fat (tallow) | Environment (T < 10 days)* | Environment (T < 10 days)* | 55 | 65 |

| Cattle / Vegetable fat (tallow) | 35 (T > 10 days)* | 45 (T > 10 days)* | 55 | 65 |

* T = journey time

1 It is recognised that in some cases the ambient temperatures may exceed the recommended maximum figures shown in the Table.

2 Hydrogenated oils can vary considerably in their slip melting points, which should always declared. It is recommended that during the voyage, the temperature should be maintained at around the declared melting point and that this should be increased prior to discharge to give a temperature of between 10 and 15oC above that point to effect a clean discharge.

3 Different grades of palm stearin may have wide variations in their slip melting points and the temperature quoted may need to be adjusted to suit specific circumstances.

4 For warmer climates, the loading and discharge temperatures for coconut oil and palm kernel oil are Min 30oC, Max 35oC or ambient temperatures

HACCP WORK PLAN 10b

PERMITTED TEMPERATURES IN THE EVENT OF DRY LOADING TRANSPORT

AIM: To protect products which are sensitive to temperature changes by way of guidelines from spoilage or other processes which are undesirable for feed or food.

The shipper is bound to follow the instructions of the client with respect to temperature control for the transport, loading and unloading of batches of food, raw materials for food, feed materials, compound feed or premixtures.

The products must be covered during transport in as far as this does not harm product quality. Where necessary, for the maintenance of product quality, there must be ventilation to prevent problems with condensation.

The principal must be informed or consulted in case of any form of serious temperature deviation.

HACCP WORK PLAN 10c

PERMITTED TEMPERATURES IN THE EVENT OF CONTAINER TRANSPORT

AIM: To protect products which are sensitive to temperature changes from spoilage or other processes which are undesirable for feed or food by way of guidelines.

The Guide to Good Practice for Road Transport (Food) specifies that the following guidelines are to be followed with respect to the monitoring of temperature control for the transport, loading and unloading of batches of food, raw materials for food, feed materials, compound feed or premixtures.

This is the internal temperature (in °C) of products.

| | Legal temperature | Advised temperature |

| Frozen fruit juices / ice | ≤ -/- 18 °C | ≤ -/- 20 °C |

| Frozen fish | ≤ -/- 18 °C | ≤ -/- 20 °C |

| Frozen butter & other fats | ≤ -/- 18 °C | ≤ -/- 20 °C |

| Frozen meat | ≤ -/- 18 °C | ≤ -/- 20 °C |

| Other frozen food | ≤ -/- 18 °C | ≤ -/- 20 °C |

| Milk products | ≤ 7 °C | ≤ 4 °C |

| Poultry & Rabbit | ≤ 4 °C | -/- 2 - 4 °C |

| Fish, molluscs, shellfish | ≤ 4 °C | in melting ice (-/- 0 °C) |

| Meat | ≤ 7 °C | ≤ 4 °C |

| Meat products | ≤ 7 °C | ≤ 4 °C |

INSTRUCTIONS RELATING TO MAXIMUM AND MINIMUM TEMPERATURE AND POSSIBLE MAXIMUM PERIODS OF TRANSPORT (with respect to storage life) WILL BE OBTAINED FROM THE CLIENT.

DEVIATIONS FROM THIS MUST ALWAYS BE REPORTED TO THE CLIENT.

HACCP WORK PLAN 11

CARGO RECORD BOOK

(Example, provided that all involved information below must be provided)

AIM: Transported loads can be effectively traced through the registration of loads

| Name of vessel: | | |||

| European vessel number: | | |||

| Loading date: | | Product: | | |

| Quantity: | | Temperature (if liquid and/or refrigerated): | On loading: During transport: On delivery: | |

| Holds – number / nos: | | Pest free | ||

| Empty | Clean | Dry | Odour-free | No load residues |

| Client / Freight Broker | | From: | To: | |

| LCI received yes/no*: | LCI number: | Date empty: | Cleaning carried out: | |

| Remarks / details / deviations | ||||

* Cross out what does not apply

HACCP WORK PLAN 12

PROTEST LETTER relating to feed and food safety checks

(Example, provided that all involved information below must be provided)

AIM: Indicating to other parties the feed and food safety risks of unchecked operations may avoid hazards.

LETTER OF PROTEST

DATE :

TO :

FROM :

RE. : Barge :

Parcel :

Place :

Ex :

Dear Sirs,

We herewith have to inform you about the fact that on the above mentioned parcel the following has been noted:

- There was no superintendent present/available.

- The loaded / unloaded parcel showed the following non-conformity

……………………………………………………………………………………..

NVWA must be warned in the event of food-unsafe and / or feed-unsafe deviations from the goods.

* This is done in consultation with the principal and / or owner of the goods concerned..

- Other non-conformities, named ………………………………………………….

We, as owner/shipper/charterer / lessor / lessee of the above mentioned ship/ pushed barge are not responsible for eventual delay and/or differences of the quality and/or quantity of the (un)loaded parcel(s).

* If required by law, a food or feed unsafe situation will be reported to the relevant authority. The Dutch authority is the NVWA and the NVWA notification form must be used for notifications of unsafe situations (see Appendix 2 Notification forms).

| International framework * If required by law, a food or feed unsafe situation will be reported to the relevant authority. |

HACCP WORK PLAN 13

SAMPLE COMPLAINTS REGISTRATION FORM

(Example, provided that all involved information below must be provided)

AIM: To record all complaints and/or other remarks relating to the safe transportation of feed or food with the purpose of improving any possible undesirable situation.

COMPLAINTS REGISTRATION FORM

Number : …………..

Sender : ………………………………………………….. Date: …………………..…….......

Customer – supplier name : ………..…..…………..….................................................

Contact person : ..…………..….................................................................

Position : …………………………….. Tel: ………………….......

DESCRIPTION OF COMPLAINT(including suspected cause) Internal / External

……………………………………………………………………………………………..……………………………………………………………………………………………………..……………………………………………………………………………………………………..………………………

Relates to department: …………………………………………………………………………

Boat/dossier number: …………………………………………………………………………...

Date registered in complaints register : …….…...............………………..……..…............

Initials for receipt of complaints registration form :..…...............………………..……..…....

Action to be taken by : ..………………………………………..…………………..…………...

Department : ……… ……………………………………………….........…………..……..…..

DESCRIPTION OF ACTION TAKEN

……………………………………………………………………………………………..……………………………………………………………………………………………………..……………………………………………………………………………………………………..………

Date action completed : ……….....................……………………………………..…

Date action reported to customer : .....................……………………………………..

Initials : ……….....................……………………………………...

Complaints register filing date : ……………………….....................………….....................

Initials for receipt : ………………………………..........…………..……..…..........................

HACCP WORK PLAN 14

REGISTRATION & DOCUMENTATION

(Example, provided that all involved information below must be provided)

AIM: To register and document all the relevant documentation for this Guide to Good Practice so that it can be seen what has happened in the past.

General:

Registration is the collection of all the data involved. Not only the agreed procedures but particularly the other data such as the inspections of the vessels, the sampling and the records of complaints must be properly registered.

Documenting is the recording of all the registered data in a documentation summary. It is of great importance that the information on the safe transportation of feed and food is properly recorded. Examples may include the inspection of loading compartments, the temperature measurement data and the details of previous loads. The conditions during transshipment and transport and the information on the products should also be recorded.

Procedure:

The data involved should be available on board the vessel for a period of at least two years (unless otherwise stated in national legislation). In the event of possible inspections this data should be able to be shown and explained. The carrier must also use a checklist that indicates which procedures have been used for a particular trip.

These procedures are:

Work Plan 3, 4 - hygiene

Work Plan 5 - cleaning loading compartments

Work Plan 6, 7, 8 - transport process

Work Plan 9 - previous loads

Work Plan 10 - minimum and maximum temperatures

Work Plan 15 - verification

Work Plan 16 - review in the event of changes (after-care)

With respect to the information on the products and circumstances during transshipment and transport, the following documents should be used:

Work Plan 1 - Information with respect to 'dedicated' transport

Work Plan 2 - Inspection of loading compartments

Work Plan 11 - Cargo Record Book (identification & traceability)

Work Plan 12 - Protest Letter

Work Plan 13 - Complaints registration

These documents should also be available on board for a period of at least two years and should be shown in any inspection.

CHECKLIST FOR PROCEDURES USED

(Example to check whether all requirements of the Guide to Good Practice are being met)

NAME OF VESSEL: ……………………………………………………….............................

SHIPPER: ..……………………………………………………………….................................

LOAD/UNLOAD LOCATION : ………………….................. DATE: ………………...…..

PRODUCT DESCRIPTION : ……………………….........…………………………….............

PROCEDURES USED

Work Plan 3,4 - Hygiene YES/NO

Work Plan 5 - Cleaning loading compartments YES/NO

Work Plan 6,7,8 - Transport process YES/NO

Work Plan 9 - Previous loads YES/NO

Work Plan 10 - Minimum & maximum temperatures YES/NO

Work Plan 15 - Verification YES/NO

Work Plan 16 - Review in the event of changes YES/NO

DETAILS:

………............…………………………………………………………………………………………………………………………....................................……………………………….….....……………………………………....................................……………………………….….....……………

HACCP WORK PLAN 15

VERIFICATION

AIM : To find out whether the Guide to Good Practice work plans lead in practice to the safe transport of feed and food and whether they meet the legal requirements.

VERIFICATION PROCEDURE

General:

Verification is checking to see if the Guide is being complied with.

There are several options for performing the verification:

- The carrier / captain regularly does this himself.

- The verification can be carried out by an approved control organisation at a specified frequency.

- The verification takes place during the periodic inspection of the verification company to which the ship is affiliated (mandatory registration in the GMP+ company database)

Expected questions:

- Are the work plans all present (16 items) and are they used.

- Are the hazards recognised and included in the work plans.

- Are the hazards sufficiently controlled.

- Does the shipper know enough about the operation and structure of the work plans.

- Are the work plans (where applicable) properly completed.

- Are there regulations from the structure of the work plans.

- Are the corrective actions always carried out.

- Do all employees know the structure and operation of the work plans.

- Is the letter of protest used.

- Is use made in the event of deviations of the quality improvement form.

- Is the system reviewed in the event of external changes.

- Are verifications recorded and registered.

Content of the work plans

WP 1 + 2 AIM: To provide information on the products to be transported which may lead to the determination of possible hazards, recognise those hazards and prevent any contamination through inspections.

WP 3 + 4 AIM: To prevent through personal and also general hygiene on

board that there is any negative effect on food safety.

WP 5a, 5b, 5c AIM: To prevent contamination by harmful elements of feed and food by cleaning loading compartments.

WP 6, 7 + 8 AIM: Ensuring that during transportation that no contamination by harmful elements of feed and food can take place.

WP 9a, 9b, 9c AIM: To prevent contamination by harmful previous loads of feed and food there should be guidelines which exclude contamination by these previous loads.

WP 10a, 10b, 10c AIM: To protect products which are sensitive to temperature differences from spoilage or other processes which are harmful to feed and food there should be guidelines to prevent this.

WP 11 AIM: To trace transported loads effectively through the registration of loads.

WP 12 AIM: Attention is drawn to feed and food safety by submitting a protest against the absence of an inspector.

WP 13 AIM: All complaints and/or other remarks relating to the safe transportation of feed or food should be recorded with the purpose of improving any possible harmful situation.

WP 14 AIM: All the relevant documentation for this Guide to Good Practice should be registered and documented such that in the event of an inspection it is possible to see what has happened in the past.

WP 15 AIM: To find out if the Guide to Good Practice work plans lead in practice to

the safe transportation of feed and food. Work plans must comply with the intention of the legal (HACCP) requirements.

WP 16 AIM: The maintenance of the (legal) changes to the Guide to Good Practice.

HACCP WORK PLAN 16

PROVISION OF INFORMATION IN THE EVENT OF A REVISION OF THE GUIDE OF GOOD PRACTICE

This work plan is carried out by the holder of the Guide to Good Practice

AIM: In the event of changes to the product to be transported or in the transportation process or in the event of legal changes, the Guide to Good Practice should be modified such that all involved parties are made aware of this in good time.

General:

Changes may occur in many forms such as:

- Composition and source of the products

- Factory modifications

- Process methods or parts thereof

- Environmental factors

- Cleaning procedures

- Types of loading tanks

- Storage and transshipment conditions

- Legal provisions

- Quality requirements

If there should be changes which relate to feed and food safety then these changes should be announced to the users as quickly as possible. Changes to legal provisions in particular should be reported in good time.

Procedure:

- Maintenance of the Guide to Good Practice will be carried out by the GMP+ International in consultation with the organisations of interested parties.

- Each structural change will be made available to all those involved.

- All changes to legal provisions will be reported to the users of the Guide to Good Practice.

APPENDIX 1

LOAD LIST FOR PREVIOUS LOADS AND CLEANING REGIMES

Four basic principles can be distinguished with respect to cleaning and disinfection. The established cleaning regimes represents the minimum necessary cleaning. If the loading compartment is not clean after the cleaning in question then additional cleaning must take place. The four basic principles for cleaning are:

| Cleaning regime | Cleaning method |

| A | Dry clean |

| B | Cleaning with water |

| C | Cleaning with a cleaning agent (Only 'food grade' cleaning agents may be used) |

| D | Cleaning and disinfection (Only 'food grade' disinfection agents may be used) |

Minimally the cleaning regime mentioned in this Appendix must be applied. The LCI, however, may require a stricter cleaning regime before releasing the loading area for loading with food and feed, but never a milder cleaning regime.

Please note:

If a product is not listed into one of the load categories in this Appendix, please consult the International Database Transport for Feed of the GMP+ Feed Certification scheme (www.gmpplus.org).

If the product has been forbidden for road transport or is not listed there either, it will be forbidden for inland shipping. If the product is categorised as requiring at least cleaning regime A, B, C or D, the product may be transported, provided that the required cleaning regime will be applied subsequent to transport.

| FORBIDDEN PREVIOUS LOADS |

(Examples of processed animal proteins are: meat bone meal, animal meal, bone meal, blood meal, dried plasma and other blood products, hydrolysed proteins (if from ruminants),, hoof meal, horn meal, poultry meal, poultry slaughter waste meal, feather meal, fat crackling, fish meal, fish pressed juice, di-calcium phosphate (animal under Reg. ( EC) no.56/2013 , gelatine (from ruminants) and all other comparable products including mixes, feed, feed additives and premixtures which contain such products). |

| MATERIALS WITH A MICROBIOLOGICAL RISK | |

| Cleaning regime | Products |

| D | Feed materials from animal origin, not belonging to forbidden previous loads. ( Examples of feed materials of animal origin are milk and milk products, eggs and egg products and animal fats). Cleaning and disinfection must take place in accordance with the applicable legislation and regulations ( (EC) No 1069/2009 and (EU) No 142/2011 ) |

| D | Microbiologically contaminated products (Salmonella, moulds) |

| D | Rail gravel |

| MATERIALS CONSTITUTING A PHYSICAL AND/OR CHEMICAL RISK | |

| Cleaning regime | Products |

| B | Alumina |

| B | Alumina (aluminate clinkers) |

| B | Ammonium nitrate. |

| B | Anhydrite (sand cement) |

| B | Barite (spar) |

| B | Basalt |

| B | Bauxite (crude and calcinated |

| B | Bentonite |

| B | Biomass |

| B | Blast-furnace slag |

| B | Borax |

| B | Bottom ash, bottom slag (Eural code 190112) |

| B | Calcium (ordinary mortar lime) |

| B | Calcium ammonium nitrate (CAN) |

| B | Calcium ammonium nitrate KAS |

| B | Cement (Portland) |

| B | China clay |

| B | Containers |

| B | Di-ammonium phosphate (DAP) |

| B | Ferrous alloys (ferrous manganese, ferrous chrome, ferrous nickel, etc) |