1. General

1.1. What is GMP+ FRA certification?

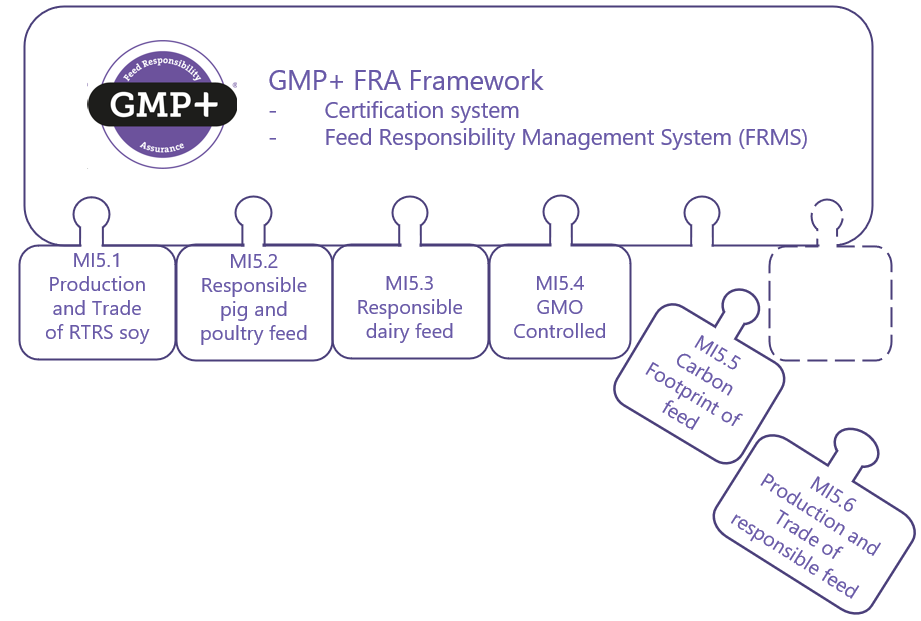

FRA stands for Feed Responsibility Assurance. As part of the GMP+ Feed Certification scheme, the GMP+ FRA module contains requirements for the assurance of the production and / or trade of responsible feed. Via independent certification, the GMP+ certified company can demonstrate compliance with the requirements for producing and / or trading responsible feed.

GMP+ FRA certification is particularly interesting for companies with a GMP+ FSA (Feed Safety Assurance) certificate. The reason for this is that the system requirements for assuring responsible feed are very similar to the system requirements for assuring safe feed. This makes it very interesting to combine both certifications: a one-stop-shop multiple certification, allowing 1 auditor to include both aspects in his audit. This saves time and money. However, the certification can also be used in combination with another feed safety certification or as stand-alone.

1.2. What documents are part of the FRA module?

The GMP+ FRA module consists of two components:

- GMP+ FRA Framework

The GMP+ FRA Framework contains the system requirements for assuring responsible feed. These requirements have a lot of overlap with the GMP+ FSA standards, such as the procedures and registrations for tracking & tracing and for the selection and evaluation of suppliers.

In addition, general system requirements (management responsibility, staff matters, internal audit etc.) are also necessary for the continuous assurance of requirements for responsible feed, just as they are required for assuring feed safety requirements.

The GMP+ FRA Framework consists of the R5.0 Feed Responsibility Management Systems Requirements.

- GMP+ MI documents

The GMP+ MI documents contain the scopes and criteria for responsible feed. These MI (Market Initiative) documents have been established in consultation with the market initiative referred to on the cover sheet and the introduction. This market party has provided the definition of responsible feed and asked GMP+ International to provide independent certification for it.

Companies who wish to be certified for a scope from one of the MI documents, always do this in combination with R5.0. The GMP+ MI document states what parts from the R5.0 apply.

1.3. How does the combined use of R 5.0 and MI document work?

All MI documents have a clear reference to the R5.0 Feed Responsibility Management Systems Requirements. All mentioned parts of the R5.0 must be implemented to ensure compliance with the requirements in the MI documents. The auditor will check compliance with both documents during the audit.

1.4. How can I combine a GMP+ FRA certification with a GMP+ FSA certification?

Although GMP+ FRA certification is possible without additional (feed safety) certification, most feed companies will apply GMP+ FRA certification as an addition to certification for scopes of the GMP+ Feed Safety Assurance (FSA) module.

To facilitate this multiple certification, GMP+ International has integrated certification for both feed safety assurance and feed responsibility assurance in a single certification scheme (the GMP+ Feed Certification scheme). This prevents overlap of requirements, ensures uniformity in standards and conditions and allows for limiting the (administrative) burden of audits and certifications. One (successful) audit can result in certification of multiple scopes.

However, it is the responsibility of the feed company to identify the overlap between the GMP+ FSA module and R5.0 Feed Responsibility Management Systems Requirements, and to implement all relevant conditions into one management system which ensures both compliance with the feed safety standards and the requirements in the FRA module. Compliance will be verified during the audit.

1.5. Do I have to make a lot of adjustments to my system to be certified for the GMP+ FRA module?

Although there are a lot of requirements – in particular in the R5.0, it is relatively easy to implement the GMP+ FRA requirements. In fact, the only thing it requires is to view your current Feed Safety Management System through different eyes. This means, for instance, that your manual must include a procedure for informing your customers about the status of the feed.

All requirements listed in chapter 4 of the R5.0 match requirements from the GMP+ FSA standards. For that reason, Annex 1 of the document contains a cross-reference table to identify the origin of these requirements.

New in the GMP+ FRA module (in relation to the GMP+ FSA certification) is the material accounting system and the supply chain models.

The material accounting system is an extensive version of a tracking & tracing system, in which you administratively document how much responsible feed you receive and how much you sell. This may not be negative.

Supply chain models describe how responsible feed is handled within the feed supply chain. These supply chain models describe the flow or responsible feed and what each individual link in the chain must control in order to deliver responsible feed.

2. MI documents

2.1. Which MI document applies to me?

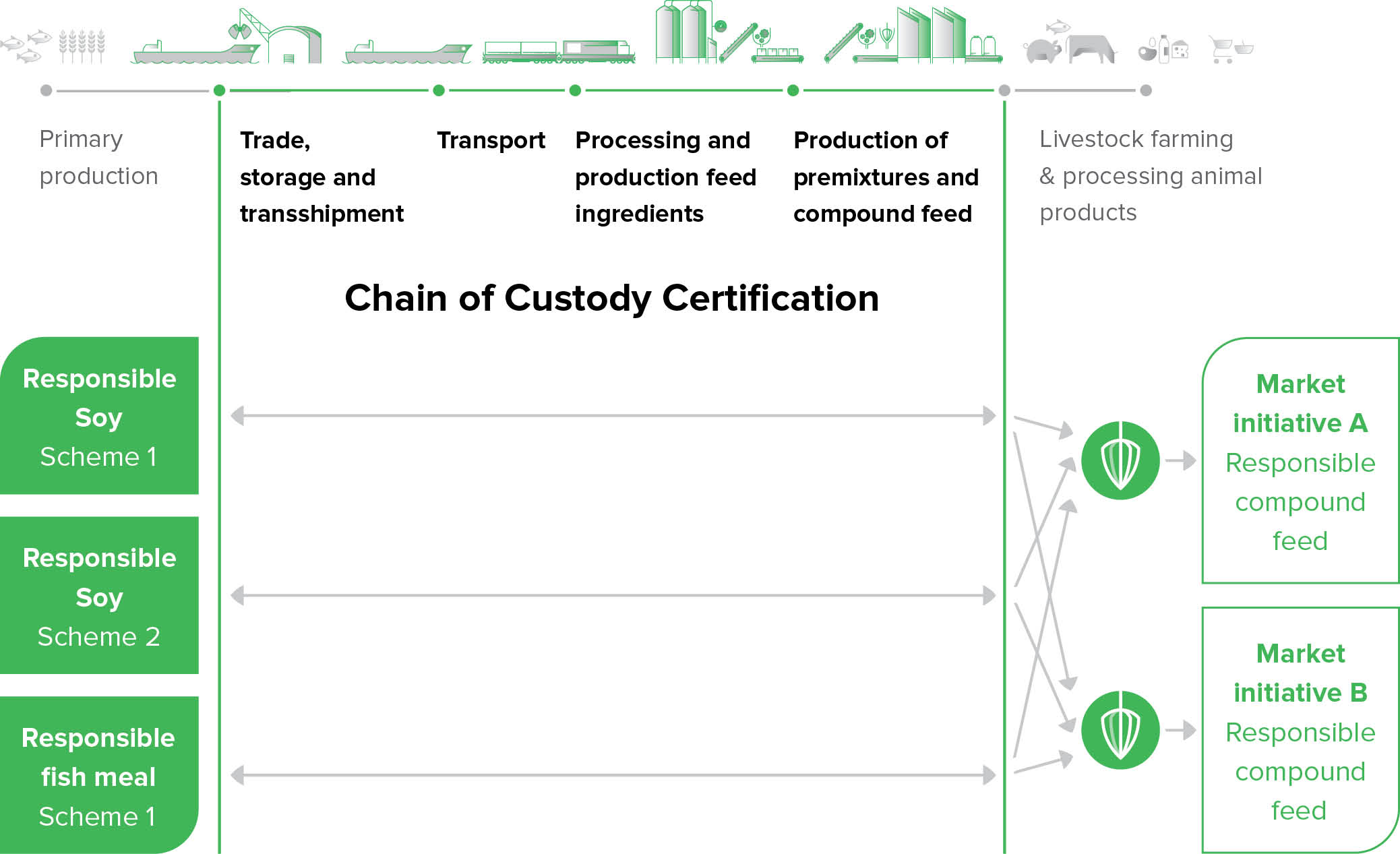

GMP+ FRA certification is not required from a GMP+ FSA perspective. However, GMP+ FRA certification may be demanded by your customer. Therefore, which MI document applies to you is largely determined by what the customer asks of you. Regardless of that, below you will find a brief overview of the various types of companies with associated (possible) MI documents. All this is in line with the following schematic representation in which a bridge is made between ‘chain of custody certification’ and the delivery to subsequent links:

In the ‘chain of custody’ (supply chain) it is unknown what an individual raw material may be used for in the end. Therefore, a certificate for sustainable cultivation is aimed at for the chain of custody. In the chain of custody, it is assured that this sustainably grown raw material passes through the chain in a correct manner.

Only at the time of delivery of a feed material or a compound feed to the farmer, the connection to a market initiative can be made. This means that the turning point is at the direct delivery to the farmer.

2.2. What is the role of GMP+ International in determining the requirements in the MI documents?

GMP+ International works with a plug-in model for the assurance of responsible feed. GMP+ International offers a so-called GMP+ FRA Framework, providing the basis for assuring responsible feed. This GMP+ FRA Framework consists of a Feed Responsibility Management System and certification requirements. Subsequently, various market initiatives can be plugged into this GMP+ FRA Framework.

GMP+ International helps formulate the requirements defined by the market initiative for responsible feed. The reason for this is that these requirements must be concrete enough to be applied and to be auditable by an auditor. However, the market initiative is the party that determines what responsible feed is and what is included in the MI document. The subcommittee Responsible Feed tests the MI document against a number of requirements, after which it can be included in the GMP+ FRA module.

The requirements for including a MI document in the GMP+ FRA module can be found in the ”Feed Responsibility Assurance Policy”.

3. MI5.1 Production and Trade of RTRS soy

3.1. What is the scope of the MI5.1 document?

The standard defines two scopes; ‘RTRS Mass Balance’ and ‘RTRS Segregation’ and can be used for:

- The production of RTRS certified soy;

- The trade of RTRS certified soy.

The applicable scope depends on the used supply chain model: Segregation or Mass Balance.

3.2. Which activities are not included in the scope?

The activities: production of premixtures, production of feed additives, storage and transshipment, road transport, inland waterway transport and affreightment (all types) are excluded from the scope.

3.3. What does RTRS consider as responsible feed?

RTRS soy does not only meet the highest environmental criteria (including a guarantee of third party-verified zero deforestation and zero conversion) but also a wide-reaching set of social and labor requirements.

RTRS certification is based on five principles:

- Legal Compliance and Good Business Practices;

- Responsible Labor Conditions;

- Responsible Community Relations;

- Environmental Responsibility;

- Good Agricultural Practices.

For the purchase of the RTRS certified soy, RTRS allows the following 2 supply chain models:

- Segregation

- Mass Balance

The use of the supply chain model Book & Claim is not allowed in the MI5.1.

3.4. Who will ask for feed that is in compliance with MI5.1?

Feed producers that want to purchase RTRS Segregated soy or RTRS Mass Balance soy will look for a supplier that is certified for the applicable scope. The feed producer can choose to buy from a RTRS Chain of Custody certified supplier or a (GMP+) MI5.1 certified supplier.

3.5. How does MI5.1 relate to RTRS certification?

The certification scheme of RTRS offers two certifications:

- RTRS Standard for Responsible Soy Production (intended for the primary production of RTRS soy)

- RTRS Chain of Custody Standard (for the subsequent links in the chain)

The scopes Mass Balance and Segregation within the MI5.1 Production and Trade of RTRS Soy are equivalent to the scopes Mass Balance and Segregation within the RTRS Chain of Custody Standard. This is also confirmed in an agreement between RTRS and GMP+ International.

Because of this, participants in the MI5.1 are permitted to use the RTRS logo and to supply to RTRS participants.

4. MI5.2 Responsible pig & poultry feed

4.1. What is the scope of the MI5.2 document?

The scope of the standard is defined as ‘Responsible pig & poultry feed’ and can be used for:

- The production of responsible soy and responsible compound feed containing responsible soy;

- The trade of responsible soy and responsible compound feed containing responsible soy.

The responsible feed is intended for pigs and/or poultry.

4.2. Which activities are not included in the scope?

The activities: production of premixtures, production of feed additives, storage and transshipment, road transport, inland waterway transport and affreightment (all types) are excluded from the scope.

4.3. Is there a difference between packed or bulk responsible Feed in the scope of application?

Trade of packed goods from responsible soy can be brought under the scope of the MI5.2. There is no difference between packed and bulk responsible feed in the scope of application. It depends on your customer(s) if you need to bring the trade of packed goods from responsible soy under the scope the MI5.2. All purchased soy and/or compound feed containing soy that is delivered and claimed to be responsible soy and/or responsible compound feed under the requirements of the GMP+ FRA MI5.2, must be considered during the audit.

4.4. What does SMK consider as responsible feed?

All soy (including soybeans, soy products and soy derivatives) in responsible pig & poultry feed, must be responsible soy. Responsible soy is defined by SMK as soy produced and traded according to the requirements in the MI5.2 document.

The MI5.2 document recognizes several standards for the primary production of soybeans and for the production and trade of feed. Recognized are standards for primary production of soybeans that are benchmarked to the requirements in the following order:

- FEFAC Soy Sourcing Guidelines 2023;

- Inspection system based on the EU Best Practice Guidelines for voluntary certification schemes for agricultural products and foodstuffs;

- Cut-off date no later than May 2009.

For the purchase of the responsible soy SMK allows the following 5 supply chain models:

- Identity Preserved

- Segregation

- Mass Balance

- Area Mass Balance

- Book & Claim

4.5. Who will ask for feed that is in compliance with MI5.2?

SMK includes in the purchasing requirements of the Certification Scheme ‘On the way to PlanetProof’ for animal products for eggs (laying hens) that laying hen farmers must purchase their feed from companies that are certified for the MI5.2. These laying hen farmers will need to ask their supplier for MI5.2 certified feed.

Of course it is possible that other Market Initiatives for pigs and/or poultry or pig and/or poultry farmers (that are not participating in the ‘On the way to PlanetProof’ Certification Scheme) require certification for the MI5.2.

4.6. What feed can be certified via MI5.2?

MI5.2 is suitable for the production and trade of responsible soy and responsible compound feed intended for pigs and poultry.

Since the requirements relate to the production and trade of responsible soy and responsible compound feed, the certification only relates to the part of the feed that contains responsible soy.

4.7. What is a credit?

If a primary producer of soybeans (farmer) is certified against a standard for responsible soybean production, the farmer is granted credits equivalent to the volume of certified soy production. Organizations that want to support responsible soy production can purchase credits. Credits can be purchased through an online platform or through a market facilitator.

4.8. What is the validity of credits?

The MI5.2 document follows the requirements from the recognized standards stated in the MI5.2 document concerning the validity of the credits. The validity of credits depends on the soy standard.

For example, for RTRS, from the moment the first company purchases the RTRS credits from the primary producer of soy these RTRS credits will be valid for 2 calendar years. The RTRS credits expire at the end of the year following their purchase.

4.9. Is redeeming of credits part of the purchase?

Yes, where the MI5.2 document refers to the purchasing of credits, this includes the step ‘redeeming’ that is part of the purchasing process.

5. MI5.3 Responsible dairy feed

5.1. What is the scope of the MI5.3 document?

The scope of the standard is defined as ‘Responsible dairy feed’ and can be used for:

- The production of responsible soy and responsible compound feed containing responsible soy;

- The trade of responsible soy and responsible compound feed containing responsible soy.

The responsible feed is intended for dairy animals.

5.2. Which activities are not included in the scope?

The activities: production of premixtures, production of feed additives, storage and transshipment, road transport, inland waterway transport and affreightment (all types) are excluded from the scope.

5.3. Is there a difference between packed or bulk responsible Feed in the scope of application?

Trade of packed goods from responsible soy can be brought under the scope of the MI5.3. There is no difference between packed and bulk responsible feed in the scope of application. It depends on your customer(s) if you need to bring the trade of packed goods from responsible soy under the scope the MI5.3. All purchased soy and/or compound feed containing soy that is delivered and claimed to be responsible soy and/or responsible compound feed under the requirements of the GMP+ FRA MI5.3, must be considered during the audit.

5.4. What does the Sustainable Dairy Chain consider as responsible feed?

All soy (including soybeans, soy products and soy derivatives) in responsible dairy feed, must be responsible soy. Responsible soy is defined by the Sustainable Dairy Chain as RTRS soy.

For the purchase of the responsible soy the Sustainable Dairy Chain allows the following 3 supply chain models:

- Segregation

- Mass Balance

- Book & Claim

5.5. Who will ask for feed that is in compliance with MI5.3?

The Sustainable Dairy Chain requires its members to include in their purchasing requirements that dairy farmers must purchase their feed from companies that are certified for the MI5.3. These dairy farmers will need to ask their supplier for MI5.3 certified feed.

The Sustainable Dairy Chain has indicated that the demand for MI5.3 certified feed applies to all feed delivered to the dairy farmer (not just for the lactating cows). The dairy farmer will concretely define for which feed he demands this certification.

Of course it is possible that other Market Initiatives for dairy animals or dairy farmers (that are not participating in the Sustainable Dairy Chain) require certification for the MI5.3.

5.6. What feed can be certified via MI5.3?

MI5.3 is suitable for the production and trade of responsible soy and responsible compound feed intended for dairy.

Since the requirements relate to the production and trade of responsible soy and responsible compound feed, the certification only relates to the part of the feed that contains responsible soy.

5.7. What is a credit?

If a primary producer of soybeans (farmer) is certified against a standard for responsible soybean production, the farmer is granted credits equivalent to the volume of certified soy production. Organizations that want to support responsible soy production can purchase credits. Credits can be purchased through an online platform or through a market facilitator.

5.8. What is the validity of RTRS credits?

The GMP+ MI5.3 document follows the requirements from RTRS concerning the validity of the RTRS credits.

From the moment the first company purchases the RTRS credits from the primary producer of soy these RTRS credits will be valid for 2 calendar years. The RTRS credits expire at the end of the year following their purchase.

5.9. Is redeeming of RTRS credits part of the purchase?

Yes, where the GMP+ MI5.3 document refers to the purchasing of RTRS credits, this includes the step ‘redeeming’ that is part of the RTRS purchasing process.

6. MI5.4 GMO controlled

6.1. What is the scope of the MI5.4 document?

The scope of the standard is defined as ‘GMO controlled’ and can be used for:

- The production of GMO controlled compound feed, feed materials, feed additives and premixtures;

- The trade of GMO controlled compound feed, feed materials, feed additives and premixtures;

- The storage and transshipment of GMO controlled feed;

- The road transport of GMO controlled feed.

6.2. What does VLOG consider as responsible feed?

The VLOG Standard is based on the GMO labelling provisions of Regulations (EC) 1829/2003 and 1830/2003. Contamination with GMOs permitted in the EU by law does not require labelling according to Regulations (EC) No. 1829/2003 and No. 1830/2003 provided that two requirements are fulfilled:

- The threshold value of the GMO content of 0.9% per feed material is not exceeded and

- The presence of the GMO content is “adventitious or technically unavoidable”.

Contamination with approved GMO content < 0.1% are generally considered as technically unavoidable or adventitious. Contamination present in quantities from 0.1% to 0.9% is considered as labelling-compliant if the business has installed and demonstrably implemented organizational measures to avoid introduction of GMO material.

Certification for VLOG or the (GMP+) MI5.4 shows compliance with these regulations.

6.3. Who will ask for feed that is in compliance with MI5.4?

Livestock farmers who deliver GMO Controlled food products (meat / milk / eggs) to the market, will ask their feed suppliers to deliver GMO Controlled feed. For these livestock farmers, it is required to feed their livestock with GMO Controlled feed in order to sell their food products such as dairy, eggs and meat as GMO Controlled products.

6.4. Does all feed needs to be covered under MI5.4 certification?

No, only the feed of which the GMP+ certified company wants to make the claim that the feed is GMO controlled. MI5.4 can be applied for all compound feed, feed materials, feed additives and premixtures. All feed that are included in the scope of certification, must comply to the requirements in the MI5.4.

6.5. Do I need to make a Risk Assessment for other products than feed materials?

No, this requirement is only applicable for feed materials. Compound feed, feed additives and premixtures are excluded for this requirement.

In case a compound feed producer uses feed materials to produce the compound feed, the result of the risk assessment of the individual feed materials is used to manage risks for the compound feed.

As with GMP+ FSA certification, the requirements in the MI5.4 do not apply for products other than feed. If a trader sells (for example) straw as bedding to livestock farmers, this is not covered with the certification.

6.6. Why does not GMP+ International or VLOG publish a list of at risk / not at risk feed materials?

It is not possible for GMP+ International to make a generic risk assessment for all feed materials that are suitable for all situations.

VLOG sets the requirement to make a risk assessment to define at risk / not at risk feed materials (that GMP+ International follows in MI5.4), but also does not provide a list of at risk feed materials to its participants. VLOG does provide some guidance in following document:

An “Assessment Aid – At Risk Feed” is available on the VLOG homepage (under ‘Further Documents / Instructions’) to assist the feed business. This document includes a table which provides an overview of where growing genetically modified plants is allowed and thus possible at risk feed origin.

GMP+ International advises the participant to use this document (among all available information) to create its own risk assessment.

6.7. Do I have to sample and test incoming compound feed, feed materials, feed additives and/or premixtures which I have classified as ‘not at risk’?

No, this is not required as part of the GMP+ (and VLOG) certification.

However, for certain feed materials classified as ‘not at risk’ sampling and testing is required.

This concerns trading companies that purchase ‘not at risk’ soy, rapeseed, canola, corn/maize, sugar beet or cotton from a non-certified supplier and deliver it directly to the customer as GMO controlled. Every year at least 1 sample and 1 test are done.

6.8. Can I purchase feed and/or services from non-certified suppliers?

Yes, if the participant has a confirmation from the supplier of the GMO controlled status of the purchased feed and complies with the requirements of the MI5.4 GMO Controlled.

See paragraph 4.4.1. of the MI5.4 GMO Controlled for the complete overview of the requirements for purchasing feed and/or services from non-certified suppliers.

6.9. What to do when my company currently has a VLOG certificate for GMO controlled feed?

When a company is currently certified for the VLOG standard it is possible to change to the FRA standard MI5.4. This can be arranged with the Certification Body which provided the VLOG certificate and has got acceptation for MI5.4 GMO controlled. Please contact your Certification Body for more information about the transition.

6.10. Is multi-site certification possible for MI5.4?

Yes, it is possible to get a multi-site certification. The requirements are described in CR3.0 Assessment and Certification of additional scopes. Your Certification Body can give more information about this possibility.

6.11. Feed materials in which GMOs cannot be tested through a PCR test may not be purchased from non-certified suppliers and sold as GMO controlled. When is it not possible to detect GMOs in feed materials with a PCR test?

It is not possible to detect GMOs in a feed material with a PCR test if:

- the feed material has a lack of sufficient DNA (genetic material). According to the VLOG document “Suitability of GMO Analysis for Feed, Raw Materials and Food” this is the case for feed materials which are strongly processed, like soy bean oil, rape seed oil and glycerin.

- the feed material does not have sufficient detectable DNA anymore. This concerns feed materials, which in principle can be tested with a PCR test, but due to process steps, show fluctuations in the DNA amount. According to the VLOG document “ Suitability of GMO Analysis for Feed, Raw Materials and Food” this concerns for example soy lecithin, sugar beet (pressed) pulp.

The VLOG document “ Suitability of GMO Analysis for Feed, Raw Materials and Food” is available on the VLOG website (under ‘Further Documents / Instructions).

6.12. According to MI5.4 I have to inform my customer about the status of the feed. Can I use the terms ‘GMO free’ or non-GMO’?

No, the claims ‘GMO free’ and ‘non-GMO’ suggest the absence of GMOs. It is technically impossible to say that there is no GMO present in a sample. Therefore the term ‘GMO controlled’ declares that the feed is produced, traded, stored or transported in compliance with the requirements of the MI5.4.

6.13. As a GMP+ certified company I want to label my products with the VLOG geprüft seal. Am I allowed to do this?

Yes, you are allowed. More information on the use of the VLOG geprüft seal can be found via the VLOG website:

https://www.ohnegentechnik.org/fuer-unternehmen/vlog-geprueft-siegel-futtermittel/vorteile

6.14. Is it allowed to use the statement ‘GMO controlled’ in Belgium?

Yes. We’ve received questions whether is allowed to use the statement ‘GMO controlled’ in Belgium (because it is thought to be conflicting with legislation). The following confirmation from the Belgium authority FAVV shows that there is no legal objection to use the GMO controlled statement in Belgium:

“I have contacted our local control authorities and according to the information in my possession, I have not received any feedback confirming that inspectors are of the opinion that GMP+ certified feed companies in Belgium cannot use the declaration “GMO Controlled”.

The FAVV controls claims on animal feed in accordance with article 13 of Regulation (EC) No 767/2009. In the context of GMP+ standard MI5.4 GMO Controlled, the "GMO controlled" claim is objective and verifiable.

We have forwarded this information to our local control authorities.“

7. MI5.5 Carbon footprint of feed

7.1. What is the scope of the MI5.5 document?

The MI5.5 document contains the requirements for the calculation of the carbon footprint (CFP) of feed and its communication towards customers or third parties.

The MI5.5 document ensures the calculation of the CFP of feed in accordance with the methodology of the Nevedi Protocol.

The MI5.5 document is applicable to the compound feed company, located in the Netherlands, producing and delivering compound feed to the buyer.

7.2. What is considered as responsible feed?

Feed of which the CFP is calculated in accordance with the methodology of the Nevedi Protocol.

7.3. Who will ask for feed that is in compliance with MI5.5?

Dairy farmers who want information about the CFP of feed delivered to the central database ‘Kringloopwijzer’.

Of course it is possible that other livestock farmers will ask for feed certified when they are interested in knowing the CFP of the feed.

7.4. What feed can be certified via MI5.5?

Currently, MI5.5 can only be applied for compound feed.

8. MI5.6 Production and Trade of responsible feed

8.1. General

8.1.1. What is considered as responsible feed?

All soy (including soybeans, soy products and soy derivatives) in responsible feed, must be responsible soy. Responsible soy is defined as soy produced and traded according to the requirements in the MI5.6 document.

The MI5.6 document recognizes several standards for the primary production of soybeans (Appendix 1) and for the production and trade of feed (Appendix 2). Recognized are standards for primary production of soybeans that are benchmarked to the requirements in the following order:

- FEFAC Soy Sourcing Guidelines 2023;

- Inspection system based on the EU Best Practice Guidelines for voluntary certification schemes for agricultural products and foodstuffs.

For the purchase of the responsible soy it is allowed to use the following 5 supply chain models:

- Identity Preserved

- Segregation

- Mass Balance

- Area Mass Balance

- Book & Claim

See Appendix 1 of the MI5.6 for the accepted supply chain models per recognized standard for the primary production of soybeans.

8.1.2. How does the certification relate to Regulation on Deforestation-free products (EUDR)?

The MI5.6 recognizes soy standards for the primary production of soybeans and systems for the production and trade of animal feed. These soy standards include several requirements, some of these are equivalent to or are above the EUDR requirements. However, not all of the EUDR requirements are (yet) present in these standards, for example the requirements concerning geolocation or due diligence of the EUDR. Also, in general, for the EUDR, there are still questions about the detailed interpretation, which may lead to detailed adjustments in the standards and EUDR verification modules. By certification for the MI5.6 you do not automatically comply with all the requirements of EUDR.

8.1.3. Will it be necessary to carry on with the MI5.6 certification after 01-01-2025 as by then there should be only deforestation free soy products in the EU?

As of 30-12-2024, all products defined in EUDR (Annex 1), including soy, need to be supported by a due diligence statement guaranteeing no deforestation and legal compliance. The EUDR only focusses on deforestation free products while the MI5.6 (and MI5.1, MI5.2, and MI5.3) focusses on responsible soy. Responsible soy not only ensures deforestation-free, but also ensures that the soy is free of conversion of other ecosystems, produced according to good agricultural practices, including for example responsible chemicals management, while respecting human rights. Additionally, many recognised soy schemes include requirements on zero deforestation and zero conversion and have more ambitious cut-off dates compared to the EUDR.

8.1.4. Is multi-site certification possible for MI5.6?

Currently, according to Appendix 2 of the CR3.0 document, multi-site certification is not allowed for the scope of the MI5.6 (Production and Trade of responsible feed). Regarding multi-site certification for the trade in responsible feed materials or compound feed, GMP+ International already tolerates this type of multi-site certification (via an exemption). Your Certification Body can give more information about this possibility. If feed is handled at a location (production), multi-site certification is not possible.

8.2. Scope

8.2.1. What is the scope of the MI5.6 document?

The scope of the standard is defined as ‘Production and Trade of responsible feed’ and can be used for:

- The production of responsible feed materials and responsible compound feed;

- The trade of responsible feed materials and responsible compound feed.

The responsible feed is intended for food-producing animals and/or pet animals.

Currently the production and trade of responsible soy and responsible compound feed containing responsible soy is addressed in the MI5.6. In the future this scope can be extended with other commodities or other ‘responsibility aspects’.

8.2.2. Which companies fall within the scope of the MI5.6?

Companies producing feed materials, producing compound feed and trading soy and compound feed containing soy intended for food-producing animals and/or pet animals.

8.2.3. Are contract manufacturers included in the scope of the MI5.6?

Yes. When production and trade companies participate in the chain, their production and trade activities need to be included in the scope of the MI5.6. Soy purchased from the contractor (see F0.2 Definition list) needs to be responsible soy and/or regular soy and compensated with credits by the purchasing company.

8.2.4. Which activities are not included in the scope?

The activities: production of premixtures, production of feed additives, storage and transshipment, road transport, inland waterway transport and affreightment (all types) are excluded from the scope.

8.2.5. What is the product scope for MI5.6 certification?

In the purchase requirements of the MI5.6 document, a reference is made to ‘soy’ (paragraph 4.2 of the MI5.6 document). ‘Soy’ is defined as ‘Soybeans, soy products and soy derivatives’ (chapter 2 of the F0.2 document). Therefore, the MI5.6 document can be applied for soy. GMP+ International does not have a list with products included or excluded under the scope. The company must decide, based on the demands of the customer, which soy it wants to bring under the certification of the MI5.6.

Currently, the standard contains only requirements to produce and trade responsible soy and compound feed containing responsible soy, therefore this certification only relates to the part of the feed that contains responsible soy.

8.2.6. What is the product scope for MI5.6 certification if there is no demand from customers?

The company must supply to its customer at minimum what the supplier requests. If the customer requests for GMP+ FRA MI5.6 certified feed, the company has to deliver GMP+ FRA MI5.6 certified feed. The company must perform a management review which includes consideration of relevant information obtained through external and internal communication, including requests related to feed responsibility from interested parties (e.g., customers and suppliers) (paragraph 4.6.3. of R5.0 document).Depending on the requests of the customer, the company can decide which soy it wants to bring under the certification of the MI5.6.

If the company does not have a request from its customer, the company can decide which soy it brings under the scope of the MI5.6, as long as the company clearly communicates the products that the company brings (and not brings) under the scope of the MI5.6 to its customer. This can be all delivered soy, but also specific soy products can be covered.

For example, some companies, when they don’t know the requirements of the end users/customers, decide to bring all delivered soy under the scope of the MI5.6.

8.2.7. What does my company need to do if we want to deliver responsible soy but contracts with customers have already been concluded for regular soy?

The regular soy can be compensated by the company by purchasing credits (Book & Claim). See paragraph 5.4 of the R5.0 document.

8.2.8. Is there a difference between packed or bulk responsible feed in the scope of application?

Trade of packed goods from responsible soy can be brought under the scope of the MI5.6. There is no difference between packed and bulk responsible feed in the scope of application. It depends on your customer(s) if you need to bring the trade of packed goods from responsible soy under the scope the MI5.6. All purchased soy and/or compound feed containing soy that is delivered and claimed to be responsible soy and/or responsible compound feed under the requirements of the GMP+ FRA MI5.6, must be considered during the audit.

8.2.9. What are the differences between the MI5.6 compared with the MI5.1, MI5.2, and MI5.3?

The documents have a different scope:

- The MI5.1 document contains the requirements to produce and/or trade RTRS certified soy.

- The MI5.2 document contains the requirements to produce and/or trade responsible soy and/or responsible compound feed intended for pigs and/or poultry.

- The MI5.3 document contains the requirements to produce and/or trade responsible soy and/or responsible compound feed intended for dairy animals.

- The MI5.6 document contains the requirements to produce and/or trade responsible feed materials and/or responsible compound feed intended for food-producing animals and/or pet animals.

Additionally, the MI5.6 document recognizes more standards for the primary production of soybeans and systems for the production and trade of responsible to purchase your responsible soy and/or compound feed containing responsible soy from compared with the MI5.1, MI5.2, and MI5.3 documents.

8.2.10. Who will ask for feed that is in compliance with MI5.6?

QS, QM Milch, and the AMA Quality Seal require companies that deliver soy and compound feed containing soy to their chain, to implement requirements of a recognized responsible soy standard as of 01-01-2024. Certification for a recognized responsible soy standard is required no later than 31-12-2024.

The MI5.6 document is recognized by QS, QM Milch, and the AMA Quality Seal. Therefore, GMP+ certified companies can use the MI5.6 document when they want to deliver responsible soy and compound feed containing responsible soy to the QS chain, QM Milch chain, and AMA Quality Seal. These customers will need to ask their supplier for MI5.6 (or equivalent) certified feed.

Of course it is possible that other Market Initiatives and/or companies (that are not delivering in the QS, QM Milch chain and/or the AMA Quality Seal) require certification for the MI5.6.

8.3. Purchase

8.3.1. Can responsible soy be purchased from a supplier that is MI5.6 certified when their supplier is not MI5.6 or equivalent certified?

Yes, when the supplier, which is MI5.6 certified, has purchased regular soy and compensated the amount by credits according to a recognised standard as included in Appendix 1 or 2 of the MI5.6 document.

8.3.2. The head office is MI5.6 certified, can they purchase responsible soy from a sub-location?

Yes, when the sub-location is certified for the MI5.6 or equivalent.

8.3.3. Should a compound feed producer demand a certificate for soybeans or soybean meal from its supplier?

The company must request the evidence of compliance with the purchase requirements from its supplier of the ingredient used - if soybeans are used in the compound feed or soybean meal. The company must show relevant documentation that the soybean meal the company purchased meets the requirements (paragraph 4.4. of the R5.0 document and paragraph 4.2. of the MI5.6 document).

8.3.4. How is responsible soy labelled when purchased from a recognised responsible soy standard?

If a company is certified according to a recognized standard for the primary production of soybeans in Appendix 1 or system for the production and trade of feed in Appendix 2, the requirements regarding labelling of the respective recognized standard apply.

8.3.5. Are credits purchased via online platforms for soybeans, for soybean meal, or for both?

It depends on the soy standard. Some soy standards draw up certificates based on soybeans and some on soy products. It is recommended to contact the relevant soy standard to determine the type of soy product for which credits must be purchased.

8.3.6. May credits for a responsible GMO Controlled soybean meal be used to compensate for the purchase (of the same amount) of non-responsible GMO soybean meal, and the other way round?

Yes. Through the purchase of responsible GMO Controlled soy credits, companies can commit themselves to responsible GMO Controlled soy production. Credits for responsible GMO Controlled soybean meal can be used to compensate for the purchase (of the same amount) of the non-responsible GMO soybean meal, however the sold product will be responsible GMO soybean meal since GMO Controlled requires segregation (MI5.4 GMO Controlled).

Credits for a responsible GMO soybean meal can be used to compensate for the purchase (of the same amount) of the non-responsible GMO Controlled soybean meal and the sold product will be responsible GMO Controlled soybean meal.

8.3.7. Can certificates for Hi-Pro soybean meal (46% protein) be used interchangeably with those for Super Hi-Pro (48% protein) soybean meal?

Yes. Certificates are being traded on product level and not on nutritional value of the product.

8.3.8. Does the country of origin matter when compensating certificates/credits?

This depends on the supply chain model that is used. For the supply chain model ‘Book & Claim’ the country of origin is not relevant. For the supply chain model ‘Area Mass Balance’ the credits must originate from growers (soybean farmers) that operate in the same area as the physical regular soy is sourced from (paragraph 5.4 of the R5.0 document). The ‘area’ depends on the soy standard from which credits are purchased from.

8.3.9. How does the version of the standard needs to be documented?

According to paragraph 4.2.1. of the MI5.6 document the version of the standard, as described in Appendix 1 or Appendix 2, must be documented. Since multiple versions of the same standard are accepted within MI5.6, it is important that there is transparency on the version of the standard. In the helpful tip of paragraph 4.2.1. in the MI5.6 document it is stated that examples of documentation are delivery notes, weighing notes, transport documents or invoices. You need to receive documentation from your supplier so that the version of the standard can be verified during the audit.

8.3.10. What is a credit?

If a primary producer of soybeans (farmer) is certified against a standard for responsible soybean production, the farmer is granted credits equivalent to the volume of certified soy production. Organizations that want to support responsible soybean production can purchase credits. Credits can be purchased through an online platform or through a market facilitator.

8.3.11. What is the validity of credits?

The MI5.6 document follows the requirements concerning the validity of the credits from the recognized standards stated in the MI5.6 document. Therefore, the validity of credits depends on the soy standard.

For example, for RTRS, from the moment the first company purchases the RTRS credits from the primary producer of soy these RTRS credits will be valid for 2 calendar years. The RTRS credits expire at the end of the year following their purchase.

8.3.12. Is redeeming of credits part of the purchase?

Yes, where the MI5.6 document refers to the purchasing of credits, this includes the step ‘redeeming’ that is part of the purchasing process.

8.3.13. Can I purchase and sell soy under Identity Preserved?

Purchase of responsible soy under the supply chain model Identity Preserved is allowed for recognized standards for the primary production of soybeans according to Appendix 1 of the MI5.6 document. Selling responsible soy under the supply chain model Identity Preserved to customers is not allowed. No requirements have been established in the R5.0 document on the supply chain model Identity Preserved.

8.4. Recognition of equivalent standards

8.4.1. Which certification schemes are accepted for purchase of responsible soy and compound feed containing responsible soy?

Appendix 1 contains the recognized standards for the primary production of soybeans and Appendix 2 contains the recognized systems for production and trade of feed.

8.4.2. Can the number and recognition status of standards be adjusted in Appendix 1 and Appendix 2?

Both Appendix 1 with recognized standards for the primary production of soybeans and Appendix 2 with the recognized systems for production and trade of feed may change regularly. Please consult the GMP+ website for the most recent version of the documents.

8.4.3. Is an organic certification of primary production of soybeans (cultivation) recognized within the MI5.6 Production and Trade of responsible feed?

All recognized standards for the primary production of soybeans are included in Appendix 1 of the MI5.6 document. Standards that are not published in the list are not recognized within the MI5.6.

8.4.4. What is the relation between the QS-Soyplus module and the MI5.6 Production and Trade of responsible feed?

The QS-Soyplus module is equivalent to the MI5.6 Production and Trade of responsible feed. QS recognizes the GMP+ (MI5.1, MI5.2, MI5.3, and) MI5.6 in the QS-Soyplus module. Companies certified for the (MI5.1, MI5.2, MI5.3, and/or) MI5.6 comply with QS-Soyplus requirements. Certification for the MI5.6 or equivalent must take place at latest on 31-12-2024 for companies to continue delivering their soy in the QS chain.

8.5. Informing the customer

8.5.1. When can my company label on accompanying documents that the responsible soy is MI5.6 compliant or that the compound feed contains MI5.6 responsible soy?

For companies delivering soy in the QM Milch chain and/or registered in the QS database and delivering soy in the QS chain that will be certified for the GMP+ MI5.1, MI5.2, MI5.3, MI5.6 or equivalent at latest on 31-12-2024, it is allowed to make a positive declaration of the status of the feed before the certification audit is conducted. A positive declaration of the status must include a clear reference to the scope of the feed (paragraph 4.5 of R5.0 document).

8.5.2. How must responsible soy be labelled when delivered under the scope of the GMP+ MI5.6?

It is the responsibility of the certified company to make the status of delivered feed or service clear to the customer:

- The status of the feed must contain a clear reference to the applied scope and must be communicated to the customer on delivery at the latest. The scopes within the GMP+ FRA Module are described in paragraph 3.5 of the F0.3 document. For the MI5.6 document the scope is ‘Production and Trade of responsible feed’.

- Only companies that are certified according to the applicable scope are allowed to make a statement about the status of the feed (See the exemption in paragraph 8.5.1. of the S9.37 document).

- Informing the customer is only required if the feed is delivered to customers who request feed that is compliant with a specific scope.

The certified company is free to choose how to communicate to the customer about the status of the feed, for example writing down in a contract with the customer which scope the feed complies with, confirming the status of the feed on the delivery slip or stating that a certain feed recipe complies with the requirements of the specific scope.

Certified companies must ensure that all invoices issued for deliveries supplied according to the requirements of the relevant standard, include the supply chain models that is/are used.

See paragraph 4.5 of the R5.0 Feed Responsibility Management Systems Requirements for the complete overview of the requirements to inform the customer.

8.5.3. When must the supply chain model be labelled?

To provide transparency to customers, also for compound feed, the supply chain model must be stated on the invoice for delivery. According to paragraph 4.5.2. of the R5.0 Feed Responsibility Management Systems Requirements, certified companies must ensure that all invoices issued for deliveries supplied according to the requirements of the MI5.6, include at least the supply chain models that are used (as described in chapter 5 of the R5.0 document).

8.6. Material accounting system

8.6.1. What is the aim of the material accounting system?

In the material accounting system purchased amounts of physical responsible soy, regular soy, and/or credits and sold amounts of physical responsible soy and/or soy that has been compensated with the purchase of credits need to be registered and must not be negative (input-output). The company has to ensure that, by use of the material accounting system, not more responsible soy is claimed and sold to customers, than was purchased as responsible soy and/or credits by the company.

8.6.2. Can internal systems and Excel files be used to set up a material accounting system?

Yes, internal systems and/or Excel files can be used to set up a material accounting system as long as the input quantities received and output quantities sold to customers are recorded. See paragraph 5.1 of the R5.0 document for all requirements on the material accounting system.

8.6.3. Is a negative periodical balance of soy credits/certificates during the fiscal year (fixed inventory period) allowed?

Yes, as long as the company ensures that at the end of the fixed inventory period the balance in the material accounting system is not negative between the quantity (in volume or weight – as specified on the credit) of credits input (credits purchased) vs output (claimed to be responsible to customers). The fixed inventory period cannot exceed one year (12 months) (paragraph 5.5.4. of R5.0 document). The fixed inventory period must be determined by the company.

8.6.4. Should a compound feed producer demand the crushing facility's conversion rate?

No, this is not necessary. The compound feed producer must identify and document all processing steps involving a change of material volume or weight. This can be based either on determining the actual quantity of each subsequent fraction, or on specifying conversion factor(s) for each processing step. When it is not possible to measure each processing step, quantities for the complete process may be used. For example, if a certified crusher purchases responsible soy, it will transfer the amount of soy into a number of products (for example soy expeller and soy oil). Within the material accounting system, the certified company can use either actual quantities or conversion factors to transfer responsible input into responsible output.

If conversion factors are used, the certified company must specify and document the methodology for calculating the conversion factor(s). The certified company must ensure that conversion factors are updated when there are changes to the production process. This must be done at least once per year (paragraph 5.1 of the R5.0 document). For example, the RTRS conversion factor system (RTRS soy footprint calculator) provides two alternative conversion methods that can be selected based on convenience. If companies have questions on the RTRS soy footprint calculator, please address them directly to RTRS.

8.7. Supply chain models

8.7.1. Can two or more batches of responsible soy certified for different standards be mixed?

Yes, the mixing of two or more different batches of responsible soy is allowed when soy is purchased from suppliers certified for recognized standards and/or systems in respectively Appendix 1 and Appendix 2.

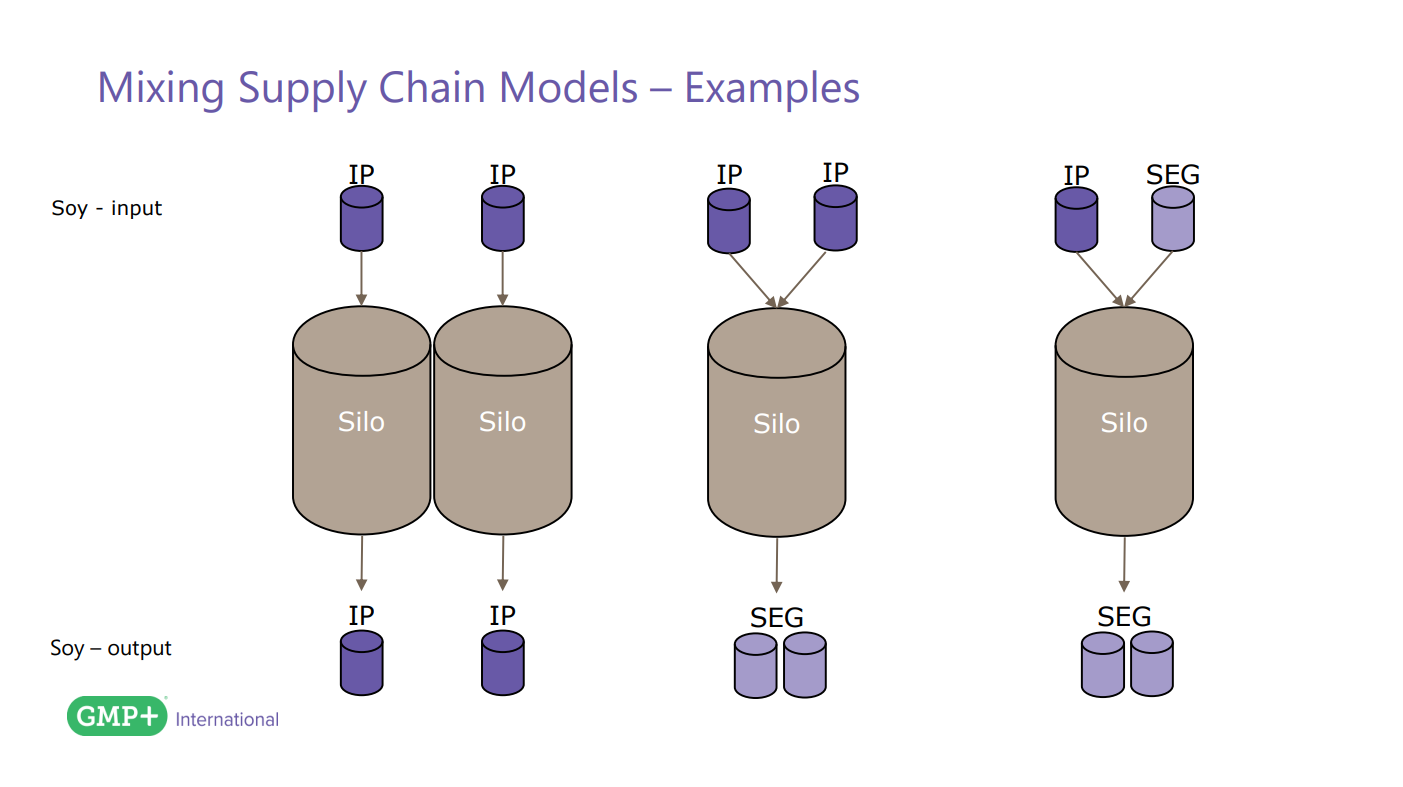

8.7.2. Can two or more batches with different supply chain models be mixed?

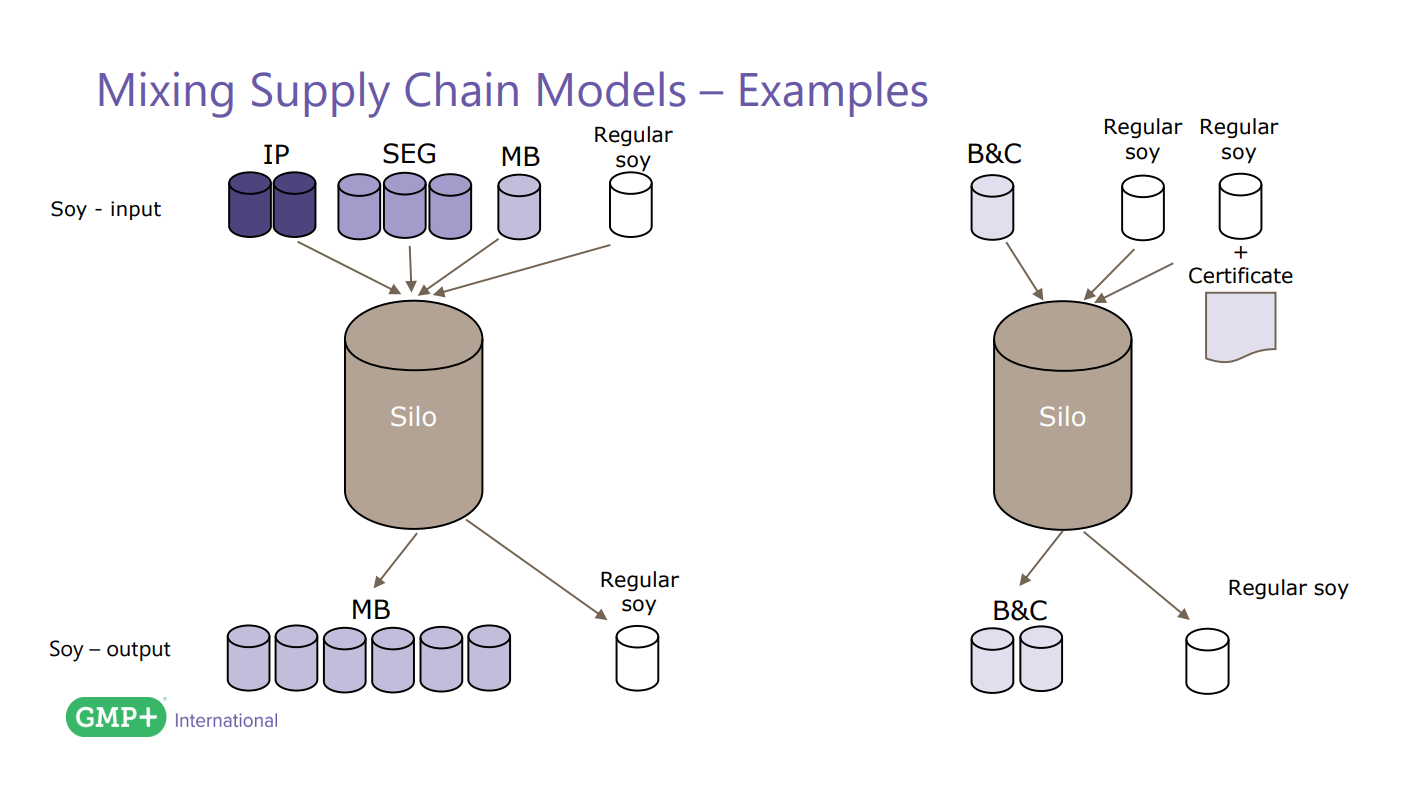

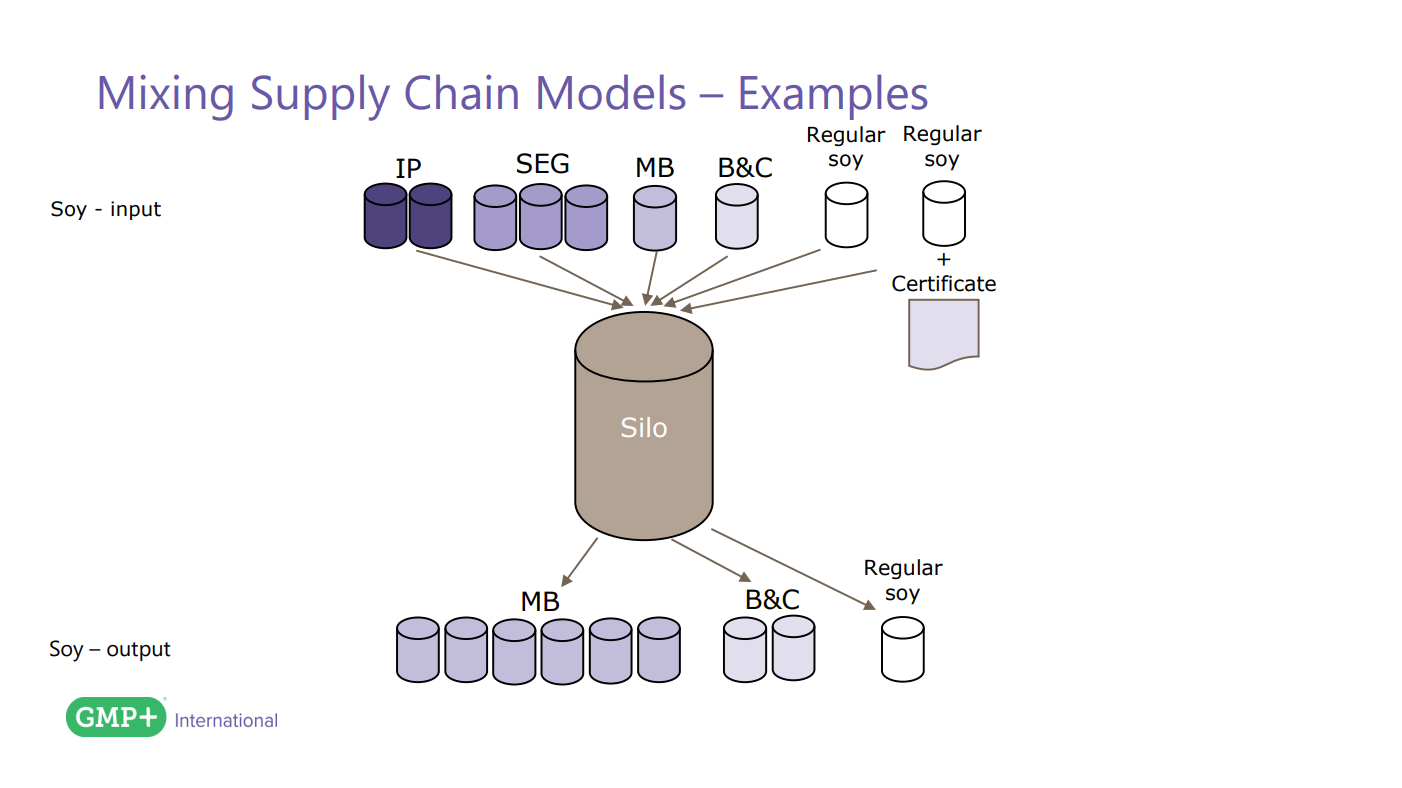

Yes. However, when mixing different supply chain models, the feed will always be downgraded to the lowest supply chain model in the following order Identity Preserved -> Segregated -> Mass Balance (except for Area Mass Balance and Book & Claim).

When Identity Preserved and/or segregated certified products are mixed with mass balanced products while abandoning batch traceability, the end product is considered as mass balanced product.

When in total 50 ton of Identity Preserved (IP), Segregation (SEG), and Mass Balance (MB) soy are purchased and 50 ton of Book & Claim (B&C) soy is purchased, and all mixed together, this soy is delivered as 50 ton Mass Balance soy and 50 ton Book & Claim soy.

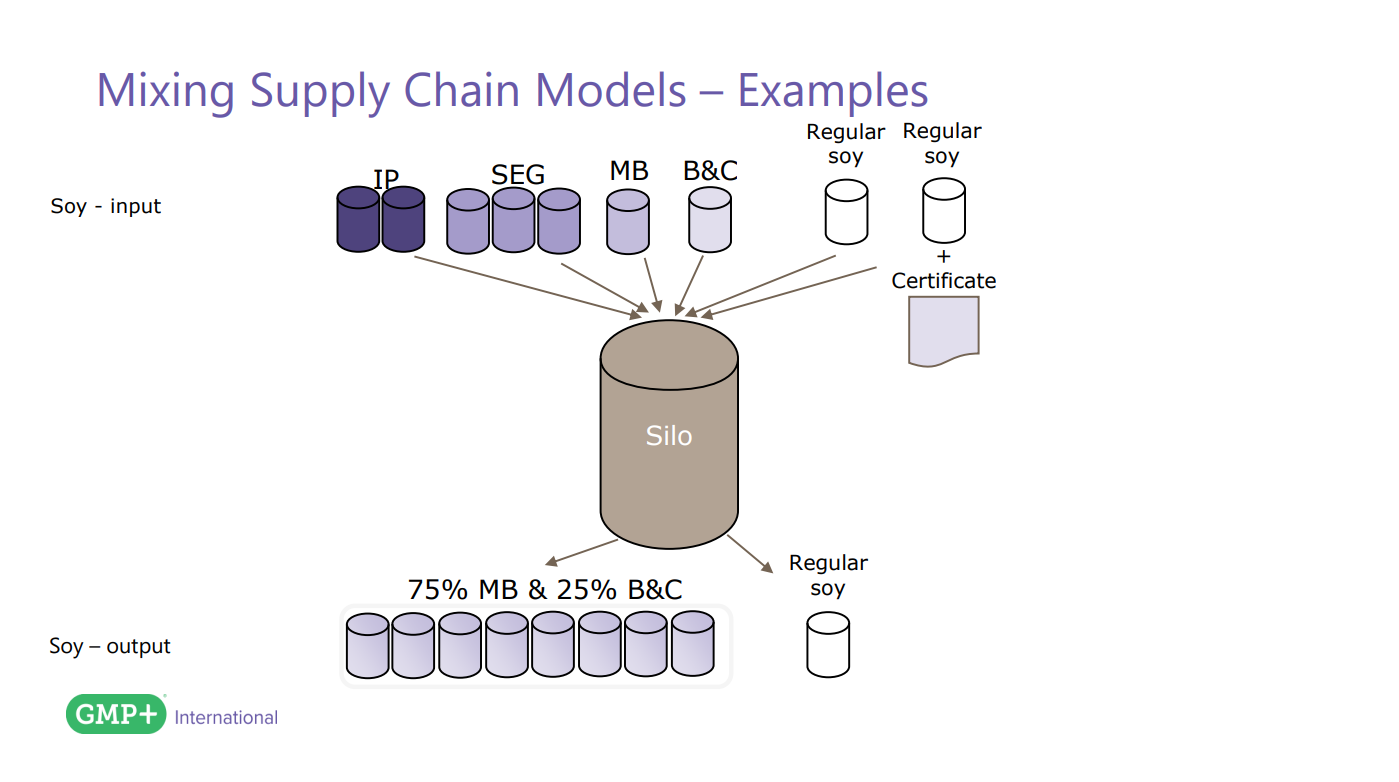

The company must include the percentage of volume/weight of each of the used supply chain models for that specific delivery (paragraph 4.5.2. of R5.0 document).

See below for some examples of mixing batches with different supply chain models:

As an example, companies can deliver and claim for total 8t responsible soy (last image):

- A volume of 6t MB and 2t B&C soy.

- A volume of 3t MB, 3t MB, 2t B&C soy.

- A volume of 8t soy of which 75% MB and 25% B&C.

- A volume of 4t soy of which 75% MB and 25% B&C, and 3t MB and 1t B&C soy.

8.8. Added value

8.8.1. What is the relevance of this certification and for which market?

Certification for the MI5.6 Production and Trade of responsible feed can provide you with several benefits, including market access, risk mitigation, and sustainability credentials:

- Market access:

Currently, the German feed and food scheme QS, QM-Milch, and the AMA Quality Seal requires companies, that supply soy (soybeans and soy products) and compound feed containing soy in their supply chain, to be certified for the GMP+ MI5.6 Production and Trade of responsible soy or equivalent at latest on 31-12-2024. There is a growing demand for sustainably sourced products. In the future, it is expected that there will be more retailers and food manufacturers demanding certified responsible soy.

- Risk mitigation:

Certification provides assurance to stakeholders, including investors, customers, and civil society organizations, that soy is produced and traded responsibly, reducing the likelihood of controversies and conflicts.

- Sustainability Credentials:

Certification demonstrates your commitment to sustainability and corporate responsibility, enhancing your brand reputation and stakeholder trust (including consumers and customers). You contribute to the transition towards a more sustainable agricultural sector.

Appendix: Cross-reference

Cross-reference between the System Requirements of R5.0 Feed Responsibility Management Systems Requirements and the relevant GMP+ FSA standards.

| R 5.0 Feed Responsibility Management Systems Requirements | TS document | ||||||

| 4.1 Feed Responsibility Management System | | | |||||

| 4.1.1 Leadership and commitment | 5.1 | | |||||

| 4.1.2 Top management’s responsibilities and authorities | 5.3.1 | | |||||

| 4.1.3 Determining the scope of the Feed Responsibility Management System | 4.3 | | |||||

| 4.1.4 Documented information | 7.5.1 | 7.5.2 | 7.5.3 | | |||

| 4.2 Prerequisite programmes (PRPs) | | | |||||

| 4.2.1 People | 7.1.2 | 7.2 | 7.3 | | |||

| 4.2.2 Traceability system | 8.3 | TS 1.1, § 10 | |||||

| 4.3 Risk Assessment | 8.5.2.2 | | |||||

| 4.4 Purchase | | | |||||

| 4.4.1 Selection of suppliers | 7.1.5 | | |||||

| 4.4.2 Verification of incoming products and/or services | | TS 1.1, § 9.1 | |||||

| 4.5 Informing the customer | | | |||||

| 4.5.1 Inform the customer about the status of the feed | 7.4.2 | | |||||

| 4.5.2 Delivery requirements | 7.4.2 | | |||||

| 4.6 Verification | | | |||||

| 4.6.1 External communication | 7.4.2 | | |||||

| 4.6.2 Internal audit | 9.2 | | |||||

| 4.6.3 Management review | 9.3.1 | 9.3.2 | | ||||